building—getting the right size joists and placing them

correctly—is very precise work.”

The newly-added, 535-square foot entranceway, which

covers two of the original five garage bays along the building

front, includes a lobby area and one classroom. The glass

storefront area and remaining bays have become glass doors

and windows that provide natural lighting for the building.

Monarc Construction cut through the masonry in the back

wall to add large windows there as well.

“It was challenging to go from warehouse to something

that’s built to be safe and suitable for occupancy by children,”

said Snyder. “There were a lot of technical requirements—

such as sprinkler systems and fire systems—that were put

in between the first and second floors to make the building

work. So it’s a small building with a lot of sophisticated

life-safety features. Our inspectors worked very hard to make

sure that everything was right and that everything was safe,

but also to facilitate and work with the inspection schedule

to make sure that they got the building open on time.”

Sustainable design

The warehouse’s existing roof required

additional bracing to accommodate the

weight and wind load of the 168 solar panels

that Bellingham had purchased for the

building. Monarc Construction also modified

the roof structure.

“The solar panels work best when they are

placed at the same elevation or same angle as

the latitude of the property,” said Bellingham.

“Typically a panel of this size would be up

at 38 degrees and facing due south. But if

you did that, you’d really stress the roof and

structure, as you will have built a big sail. So

we put the panels on a five degree elevated

ballasted system to hold them down if there’s

a heavy wind.”

Since Easter Seals’ budget wouldn’t stretch to cover the

cost of the solar panel system, Bellingham built it for them

and will get the renewable energy credits from the U.S.

government for a few years. When the tax breaks expire,

Bellingham and his wife will donate the solar panels to

the organization. “They’ll get the complete system and the

energy generated from it,” said Bellingham.

“The photovoltaic solar panels are producing more than 50

percent of the energy consumed in the building, around

46,000 kilowatt-hours per year. It’s one of the biggest systems

in northern Virginia,” Bellingham added. “Most days it will

produce more power than they need, and Dominion Power

buys that excess electrical power and puts it into the grid.”

(That arrangement also provides renewable energy credits

(SREC) for the utility power company.)

One green feature that Easter Seals can’t use at this time

is the geothermal system that Monarc Construction had

planned for its headquarters, which would have reduced the

building’s operating costs by 30 to 35 percent compared to

the cost of standard electric or gas-fired heating and cooling.

Monarc Construction had already dug five deep wells that

would be used to draw the 54-degree water—the thermal

sink for the system—from the ground.

But Easter Seals, again constrained by budget, could not

afford to build a basement or extra space above ground to

house the required equipment. So the wells remain on the

site, capped by manholes. “They are available for Easter Seals

to use later, or if some of the other properties in that block

are redeveloped, they could be hooked up to it,” said Snyder.

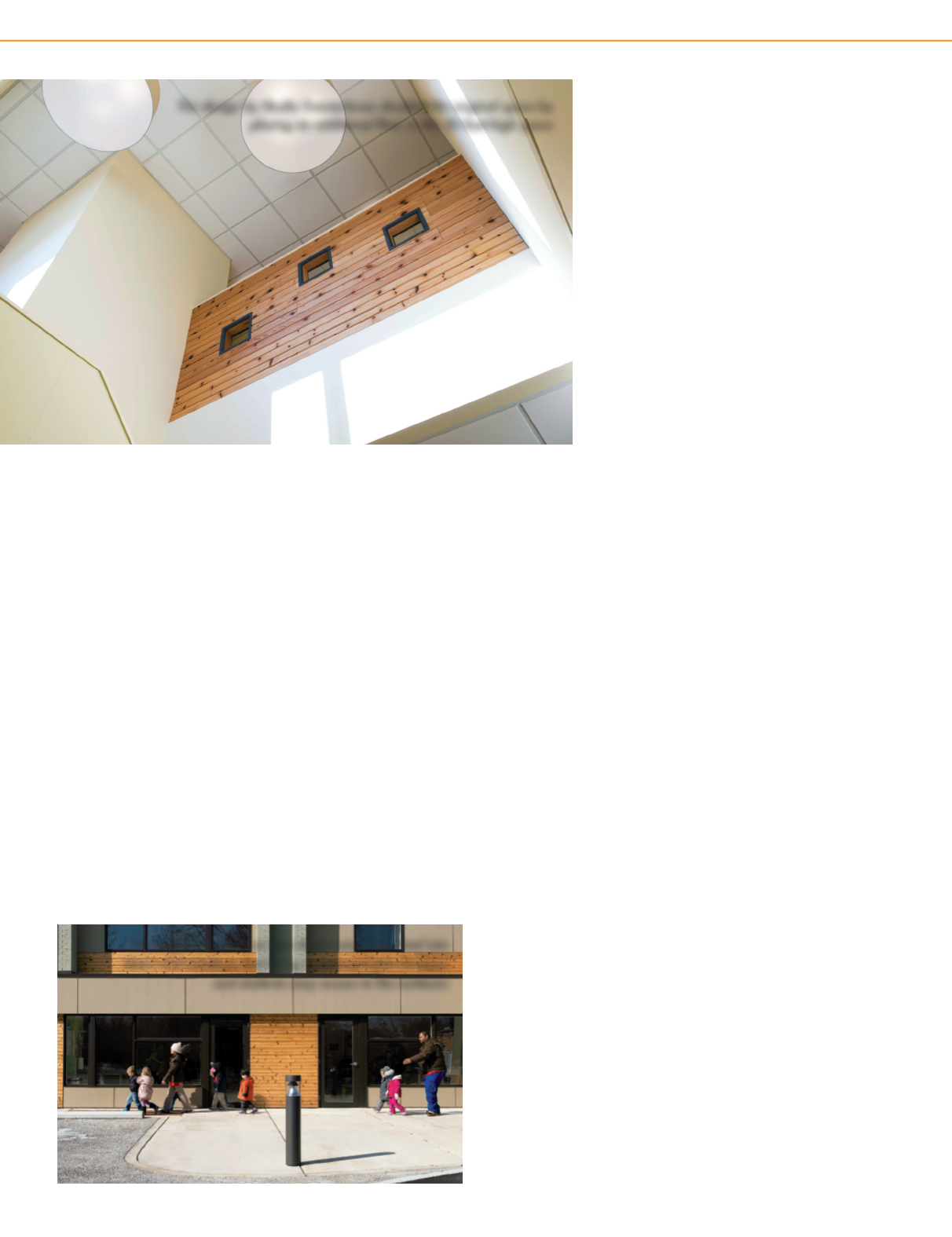

The design by Studio TwentySeven doubled the original space by

placing an additional floor in the 22-foot-high space

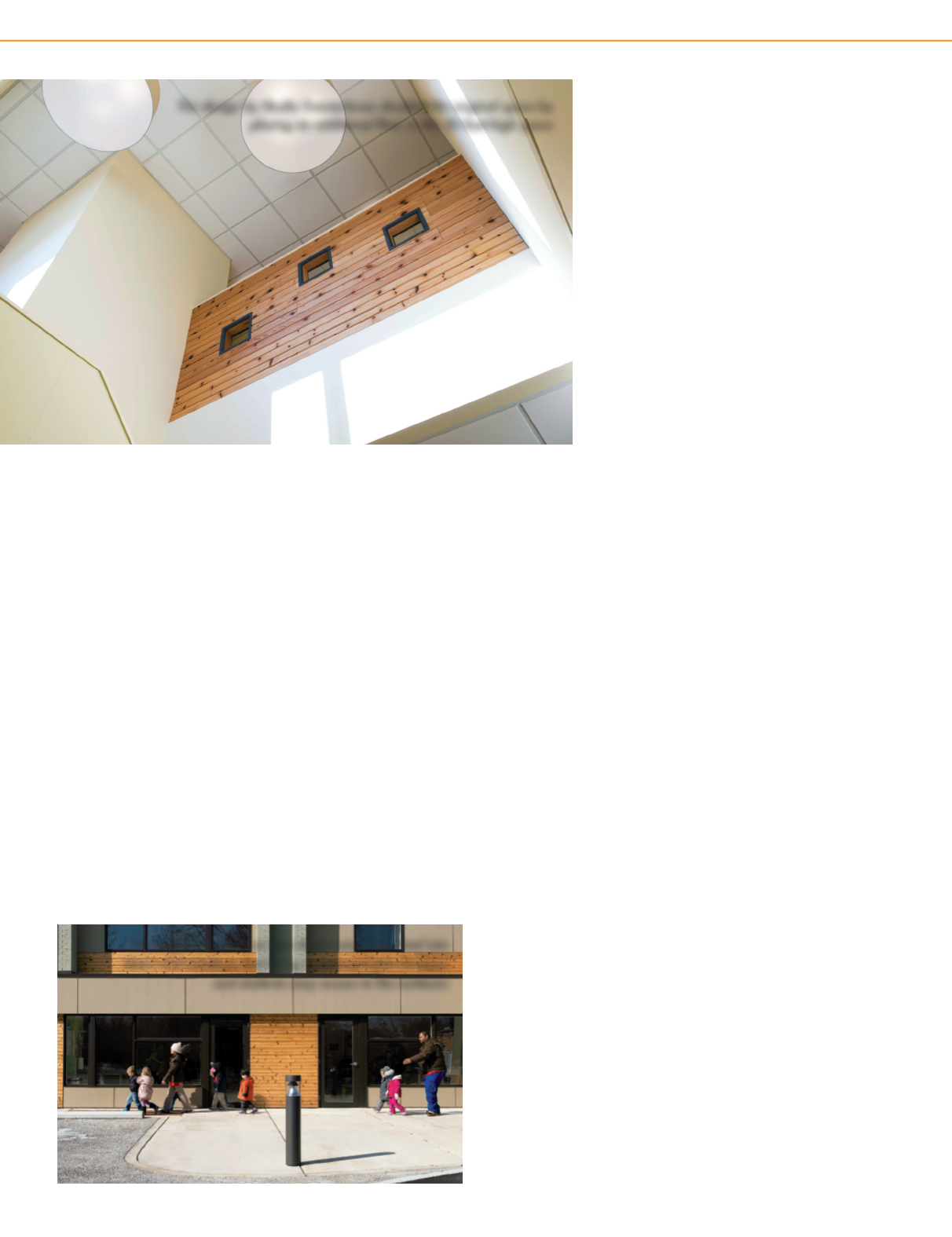

The original warehouse bay doors were converted into

doors and windows that bring in light and give teachers

and students easy access to the outdoors

Building Washington 9