FALL 2014 | MARINE TECHNICIAN TODAY

21

wide range and you get what you pay for. Additives are selected

to support the final product and vary for motor oils, gear oils

and transmission oils. These different applications require the

oils to function in specific ways to provide lubrication for the

specific application.

API Classification

It has been said, “If you don’t know where you’re going, you

probably won’t get there.” When formulating lubricating oils, this

is more a law than a quaint phrase. It is imperative to know the

required functions and performance of the finished oil prior to

starting the design. The API (American Petroleum Institute) forms a

committee to collect the requirements from the Original Equipment

Manufacturers such as General Motors, Ford, Toyota, and Cummins,

etc. Then the OEMs and the major oil companies hammer out

the specific lubricating properties for a proposed classification.

A series of performance tests are selected or developed and

certified by the ASTM (American Society for Testing Materials) for

qualifying prospective oils that meet the classification standards.

Following this, the oil manufacturing company can begin to develop

formulations of finished lubricating oils for testing to ensure they

meet the latest API classifications.

NMMA Classification

In addition to the API classification, oils formulated for use in

water craft are classified by the National Marine Manufacturers

Association. Marine engine oils are formulated to meet the high

stress conditions of continuous high RPMs and heavy loads

associated with marine propulsion. Additionally, marine applications

require rust and corrosion inhibitors be added to enhance anti-

corrosion/rust performance. Marine oils are formulated different

than auto oils for good reasons, and using auto oil for your marine

engine is a serious error.

Blending the Finished Oils

Blending lubricating oils is part science and part art. Experience is

as important as hard chemistry. The results one might expect for a

given chemical equation are not always exactly what you experience

with the finished product under real-world evaluation. Field trials

are sometimes the only reliable tests to determine how a particular

formula performs. Because of this, most companies begin in the

lab with expected concentrations of additives and perform the

required certification tests. The results of the lab tests help make

adjustments to the additives and maybe the base stock as well. The

level of quality demanded by the manufacturer will determine how

much time is spent trying to achieve the best balance with regard

to additives. The quality and type of base stock oil will affect how

much of a particular additive must be used to overcome a weakness

in the base stock oil. For example, petroleum oils are particularly

susceptible to oxidation and require oxygen stabilizers whereas

synthetic PAOs resist oxidation naturally and require minimal

oxygen stabilizers.

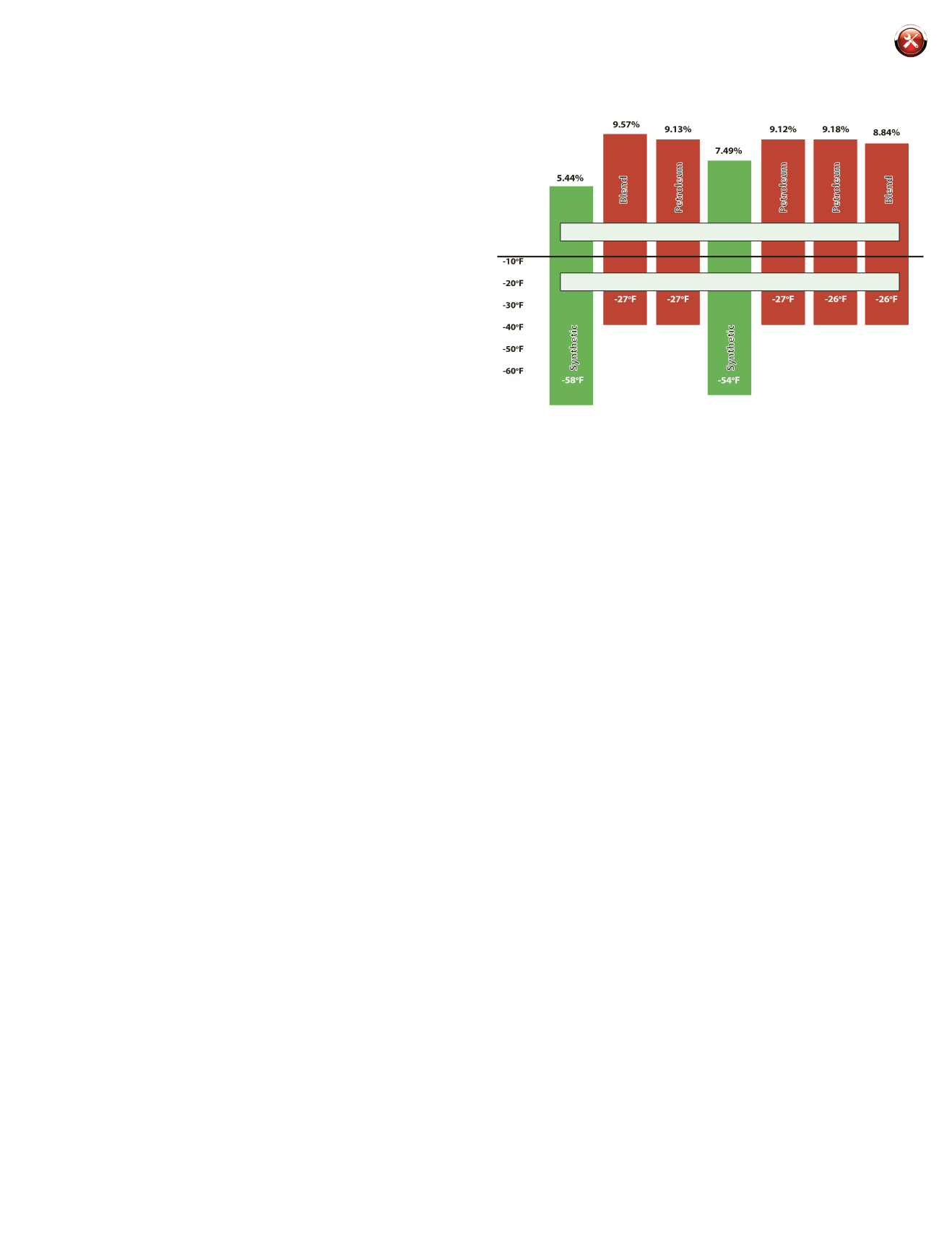

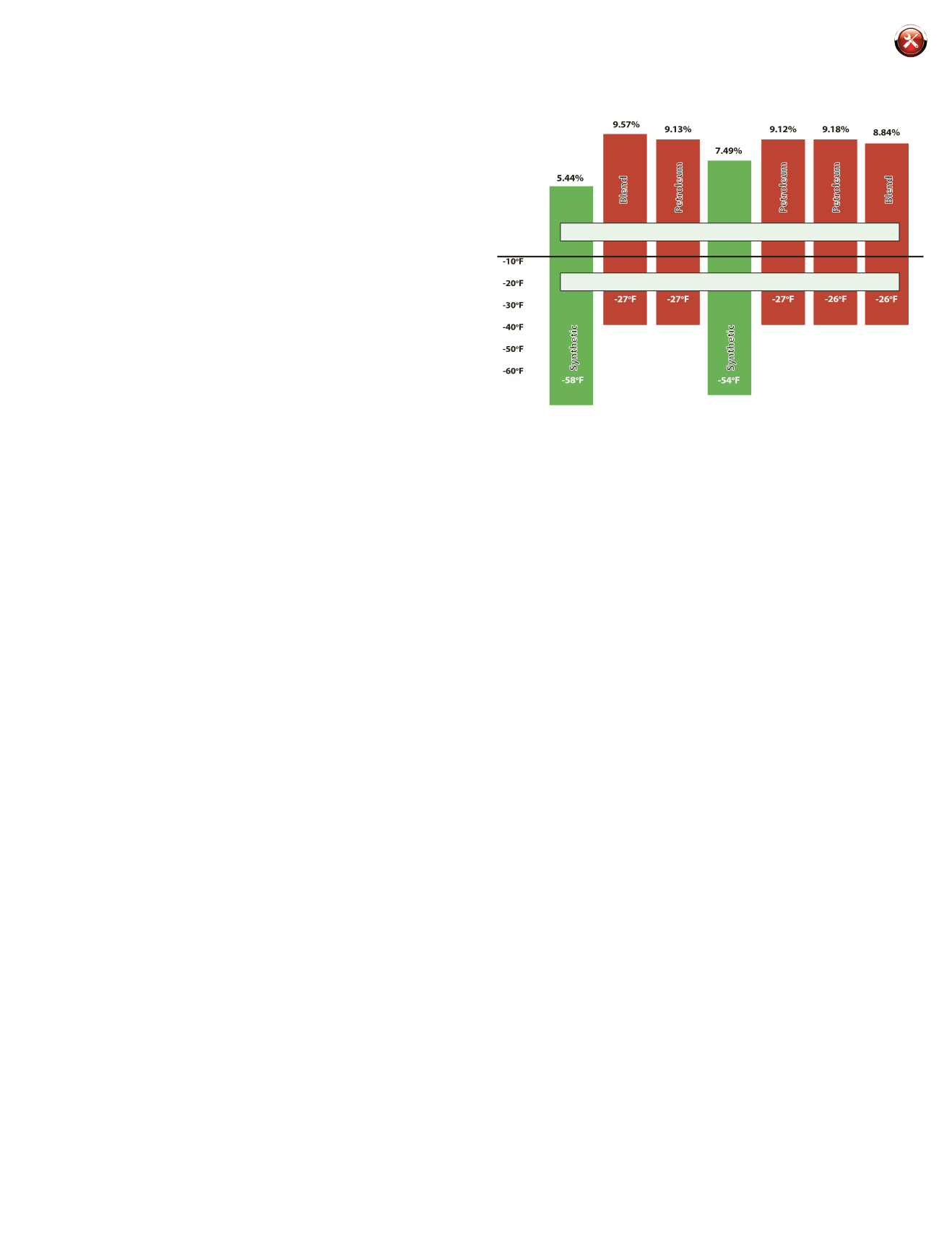

As you can see by the upper half of the graphic (Figure One),

synthetics are much less volatile than petroleum oils. Uniform

molecular structure reduces the evaporation of lightweight

molecules, enhancing the synthetic oil’s ability to endure elevated

temperatures without thickening. On the other hand, the purity of

the synthetic base oils – contaminates such as wax are eliminated

– allows for significantly lower pour points and, in turn, easier

starting in cold weather conditions (lower half, Figure One).

Once the correct blend of additives and base stock oils is

determined and all lab tests and selected field trials are complete,

mass production begins. Oils are blended in various size tanks and

mixed to ensure uniform concentrations. The quality employed by

the blending team is directly reflected in the consistency of the

finished product. Samples are drawn and compared to required

chemistry to ensure the blend is acceptable and that the containers

are filled with oil meeting the specifications on the label. Quality

varies within the industry. Every year, spot testing around the

country reveals oils that do not meet the standards proclaimed on

the label of the container.

It is a shame these reports of failed spot checks are not published

for the public to see. Companies are sometimes fined, but it

would be nearly impossible to find any paper trail of these fines.

Remember, you usually get what you pay for.

You may have heard the statement, “Oil is Oil; there’s really

no difference. It doesn’t wear out; it just gets dirty.” Hopefully,

these articles have helped you to see this statement as a silly

oversimplification of the actual complexity of lubricating oils. Next

time, I will shift gears and compare petroleum-based oils with

synthetic based oils. We will investigate when it makes sense to

use one or the other of these oils.

For questions or comments contact Dan Watson, Certified Lubrication

Specialists STLE, at the following:

800-370-2986 or

MANAGEMENT TIPS

S

.

Not all oils are created equally. The above chart shows the performance of seven

motor oils in two categories: oil evaporation expressed in percentage and pour

point expressed in degrees Fahrenheit. The two better performers (green) relative

to the others are synthetics; the second from the left, the poorest performer listed,

is a synthetic blend – as is the oil furthest to the right.

Comparing Motor Oils: Petroleum, Synthetic and Blends

(Figure One)

Evaporation / Volitility (ASTM D-5800)

Pour Point (ASTM D-97)

10%

8%

6%

4%

2%