FALL 2014 | MARINE TECHNICIAN TODAY

23

Marine Electronic

Fuel Injection

and

Performance Boater

M

ost marine technicians familiar

with sterndrive EFI can trace

its introduction into the

marketplace to the early 1990s. There were

offerings based on General Motors and Ford

engines. 1993 is often the recognized year

of the introduction, but it was not. It was

really many years earlier. The forgotten fuel

injection engine was offered by MerCruiser

from 1987 through 1989, six years earlier!

It was called the 320 EFI. It used a General

Motors 350 CID block and a totally GM designed EFI system. In fact, the

system was very similar to the tuned port injection used on GM’s Firebird

and Camaro in the 1980s.The EFI system was ahead of its time for the

marine industry, and there was no consumer demand yet, so MerCruiser

dropped it from its model lineup mid-year 1989.

Because of the re-introduction of EFI, 1993 was a new era for the marine

industry. With help fromGM’s Powertrain & Delphi, MerCruiser introduced

an EFI system that used an ECM (Electronic Control Module) called MEFI-

1(Marine Electronic Fuel Injection). To compete with MerCruiser, OMC

introduced a system with the help of Ford on a 5.8 liter engine using Ford’s

EEC (Electronic Engine Control) EFI module.

Since MerCruiser was a much larger supplier of sterndrive power

packages than OMC, the GM designed system was the most prominent

in the industry. Also GM heavily marketed the new computer controller

(ECM) for the marine industry. The improvements promoted were turn-

key starting, improved emissions, maximized spark advance due to sensor

inputs, reduced spark knock, keeping the stoichiometric ratio correct for

altitude changes, over-speed protection, reduced RPM if a critical problem

is identified by the engines computer, self-diagnostic capabilities, and data

output for aiding a technician in troubleshooting engine running problems.

As technology progressed, GM introduced MEFI-2, MEFI-3 and MEFI-4

ECMs. As the versions changed, the processors got more powerful, fuel

mapping was improved, and more fault codes could be stored to aid the

technician in troubleshooting problems. The MEFI-4 ECM supersedes all

the older versions, and if you have a failure of an older ECM, it must be

updated to the new version. A wiring harness kit comes with the new ECM

to adapt the old wiring harness to the new ECM.

The MEFI ECM system is referred to as a speed-density system. The

ECM receives information from sensors that measure engine speed and

air density. The engine speed information is supplied from the ignition

systems distributor and the air density information is supplied from the

MAP (manifold absolute pressure) sensor. The distributor tells the ECM

what the engine speed is and controls sparkmanagement. TheMAP sensor

tells the ECM about the air flow through the intake manifold and assists in

determining engine load. When throttle is advanced, vacuum drops in the

intake manifold and the air pressure density in the intake manifold rises.

THE

PERFORMANCE

CORNER

By JohnMosetti

.

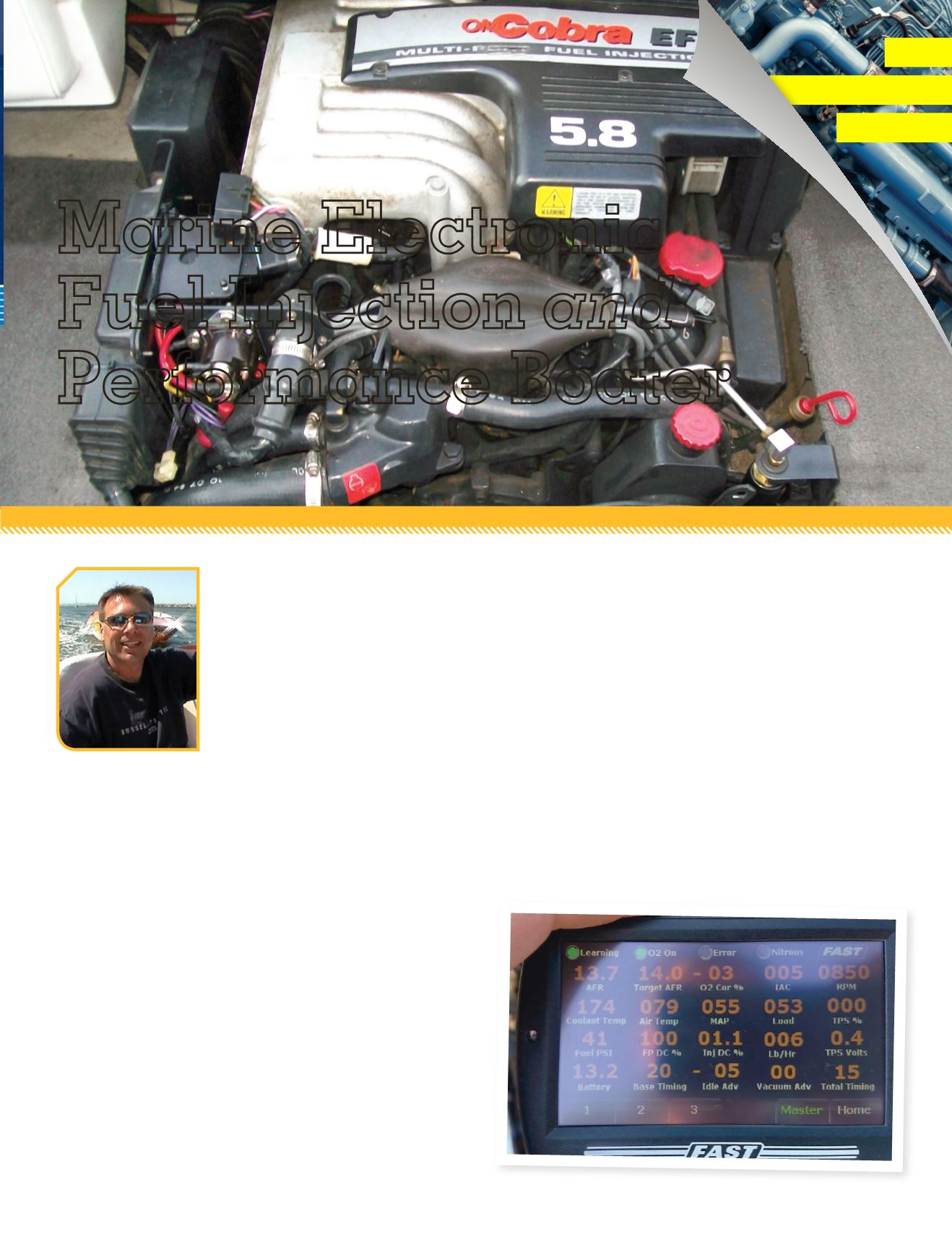

OMC Cobra 5.8 Ford marine

fuel injection engine

.

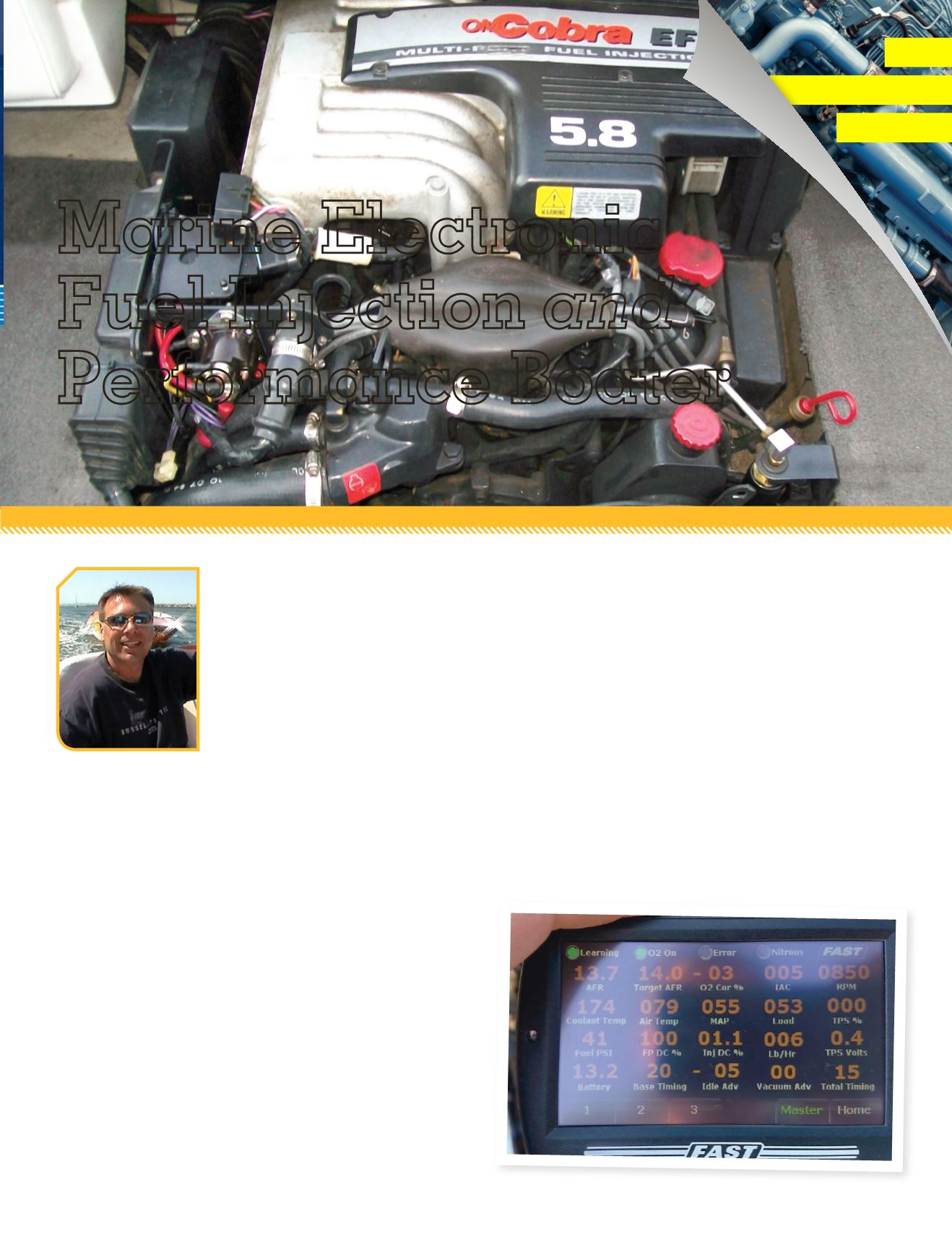

FAST Self leaning EFI system