FALL 2014 | MARINE TECHNICIAN TODAY

9

to reach down to recessed screws easily, plus they are invaluable for

carburetor repair. Replace the blades when screwdriver tips start to wear

to save your knuckles and to prevent component damage when they slip

off the screw head. Professional tool companies replace worn blades at

no cost as long as they were not used as chisels or prybars.

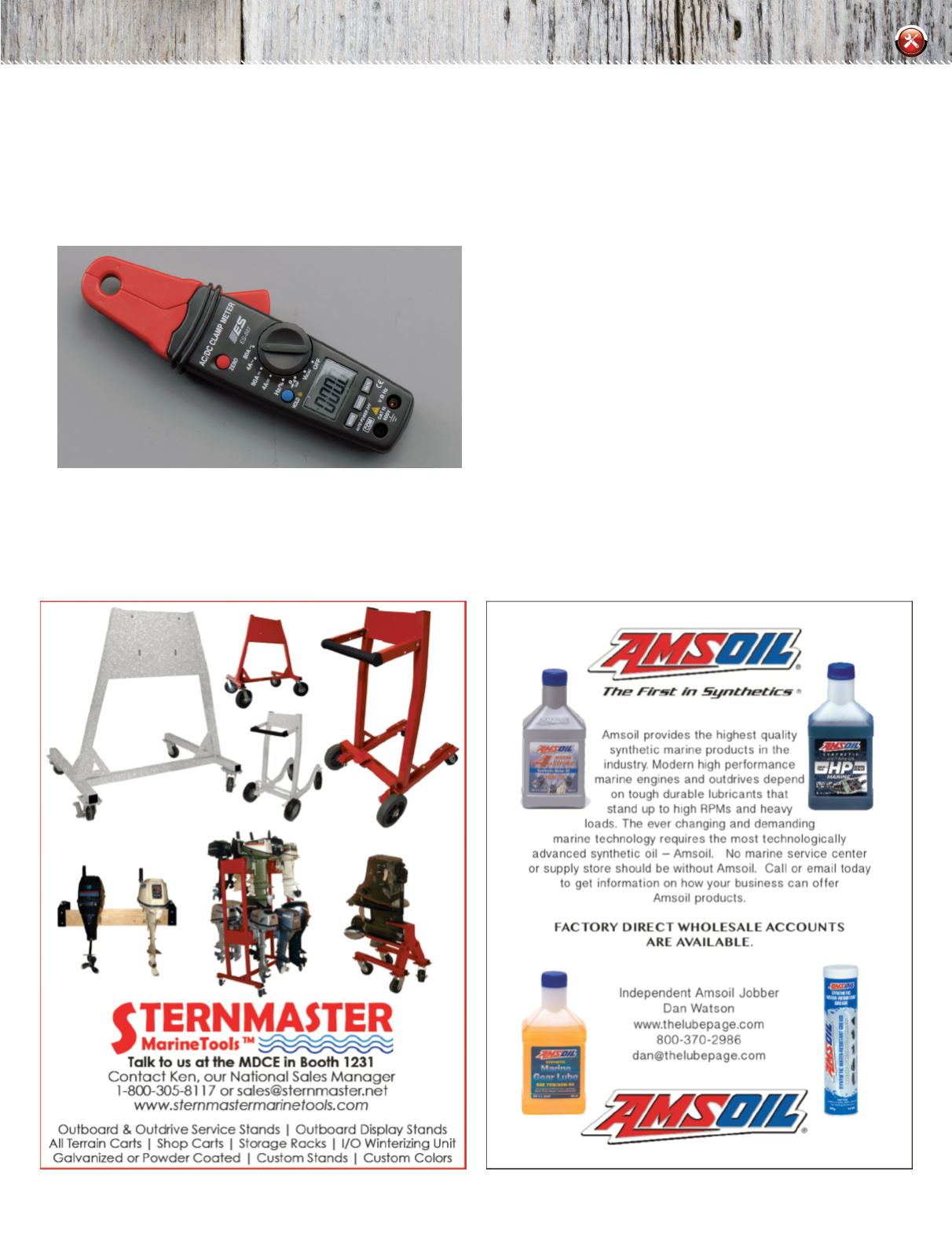

Because of the humid environment around boats, electrical problems

are possibly the most common service complaint, especially in saltwater

areas. Instead of carrying several different meters I have found that a

clamp-on current probe with a built-in multi-meter to be the handiest tool

of all. Charging problems on both outboards and inboards along with

blown fuse situations call for an ammeter, an ohmmeter, and a voltmeter

to find the culprit. Having a tool that functions as all three saves time

and effort when troubleshooting. Current readings are simplified by just

clamping the jaws over a wire and observing the amperage displayed

on the screen. Use the included test leads for the other circuit test

procedures. The ESI #687 DMM/Amp Probe is my “go-to” meter for

almost every electrical situation in a boat.

The above tools and tips came from learning many things the hard way,

from trying new items as they came on the market, and from the lessons

from those memorable old characters who took me under their wing

so many years ago. I hope that every one of you in the repair business

benefits at least a little bit from this article and will someday pass your

wisdom and experiences down to others.

TODAY’S TECHNICIAN

.