16

MARINE TECHNICIANTODAY | SUMMER 2015

TECH TALK

In 1991, the NLGI developed a classification system specifically

targeting automotive greases (Table One). For the majority of readers,

it is the appropriate rating system for your applications.

So when you are looking to purchase grease for your truck, look for grease

labeled GC-LB: grease rated for severe duty for the wheel bearings as

well as for the chassis. Multi-purpose grease is the correct match for

chassis and wheel bearings but heavy duty grease is the better choice

for extreme loads exceeding 10,000 pounds. Synthetic greases will

provide the best protection over the widest temperature range. Heavy

duty grease is moly-fortified (molybdenum disulfide) which provides for

extreme pressure lubrication. I have explained the difference in extreme

pressure lubrication vs standard lubrication regimes in an earlier issue,

so please refer to that issue for the specific explanation. There are

several legitimate extreme pressure grease points on heavy duty trucks;

using the correct grease is critical for proper operation and long life.

If the grease will be exposed to water, either by submersion or by spray,

using water resistant grease is the best choice. To be water resistant,

the grease must pass additional testing that insures its ability to cling

to a surface while being sprayed with a stream of water. Water resistant

greases contain additional thickeners and tackifiers that allow them to

resist washing out. Sometimes, these greases will be labeled “marine,”

but more and more they are simple referred to as water resistant.

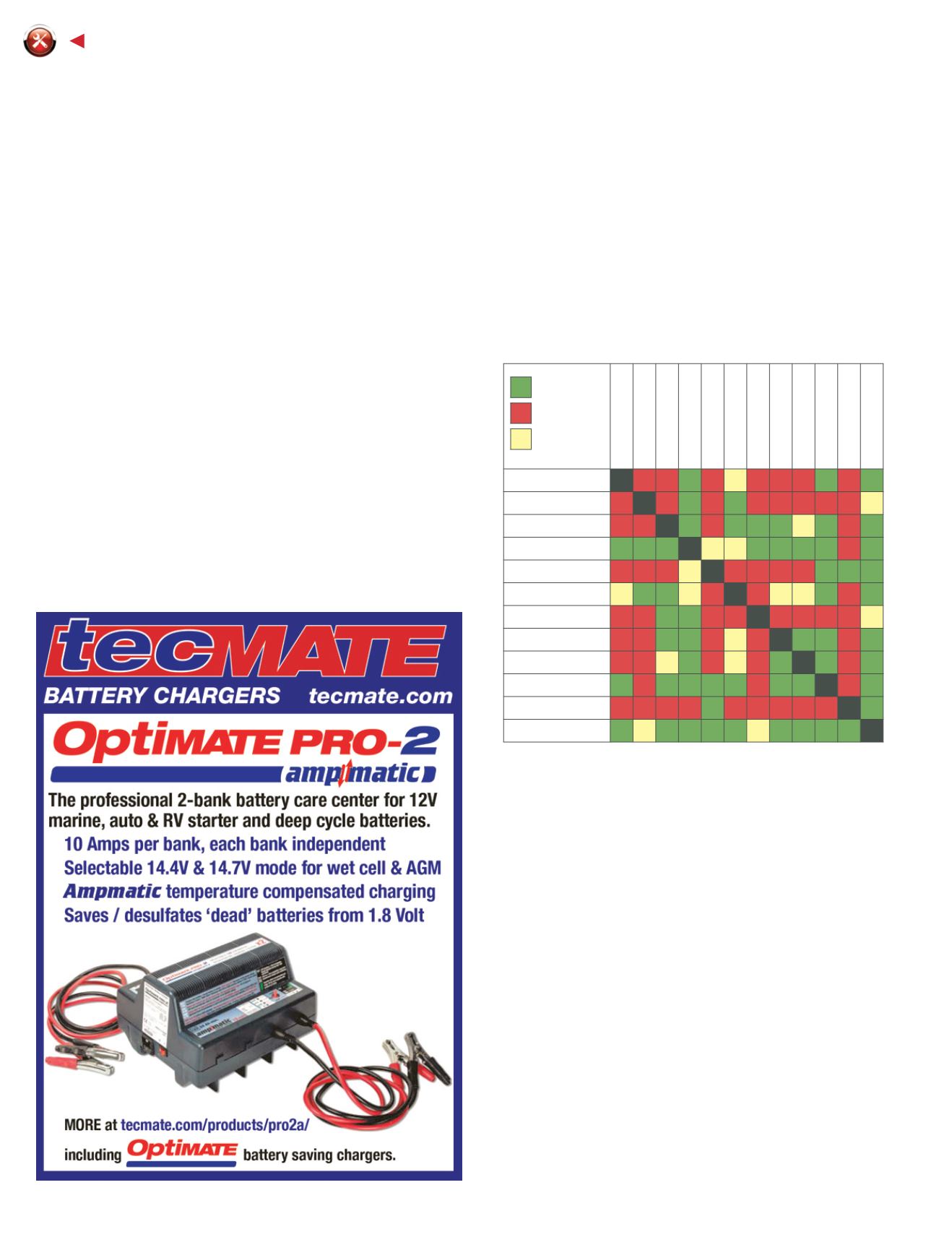

GREASE COMPATIBILITY

A word of caution; not all greases are compatible with each other. This

problem occurs because some of the thickening agents chemically

react with others, which can lead to the grease becoming very hard or

liquefying or preventing the oil from leeching out to provide lubrication,

essentially rendering the grease useless. Grease comes mixed in

a variety of thickeners (soaps) such as, lithium or lithium-complex,

calcium compounds, barium, aluminum to name a few: they are not

always compatible with each other. Table Two covers compatibility/

incompatibility of commonly-used greases. If you find grease that uses

a different thickener than those listed, contact me to verify compatibility.

Grease is the forgotten lubricant. It just doesn’t rise to the level of notice

of other lubricants; however, grease is fundamental to proper care for

your boat trailer, out-drive and vehicle. For most applications, greasing

should be done at three month intervals for petroleum and six month

intervals for synthetics. Wheel bearings properly packed with synthetic

grease are good for 10 years, but trailer bearings need to be full to

prevent water intrusion. Bearing buddies are a good addition to trailer

hubs. There are few automobile manufacturers stipulating wheel bearing

maintenance, and some are now installing sealed bearings that cannot

be greased. Ball joints and steering joints can still be greased in most

heavy duty vehicles, but in light duty vehicles, the grease fittings may not

be installed and you will have to purchase them and install them. As with

all lubricants, synthetic greases outperform petroleum greases, and the

cost difference is actually in favor of the synthetics; you simply use less

grease over time and the upfront cost difference is minimal.

For questions or comments contact Dan Watson, Certified Lubrication Specialists STLE,

at the following

800-370-2986 or

Aluminum Complex

Barium Complex

Calcium Stearate

Calcium 12 Hydroxy

Calcium Complex

Calcium Sulfonate

Clay Non-soap

Lithium Stearate

Lithium 12 Hydroxy

Lithium Complex

Polyurea Conventional

Polyurea Shear Stable

Aluminum Complex

I

I

C I

B I

I

I

C I

C

Barium Complex I

I

C I

C I

I

I

I

I

B

Calcium Stearate I

I

C I

C C C B C I

C

Calcium 12 Hydroxy C C C

B B C C C C I

C

Calcium Complex I

I

I

B

I

I

I

I

C C C

Calcium Sulfonate B C C B I

I

B B C I

C

Clay Non-soap I

I

C C I

I

I

I

I

I

B

Lithium Stearate I

I

C C I

B I

C C I

C

Lithium 12 Hydroxy I

I

B C I

B I

C

C I

C

Lithium Complex C I

C C C C I

C C

I

C

Polyurea Conventional

I

I

I

I

C I

I

I

I

I

C

Polyurea Shear Stable C B C C C C B C C C C

Table Two – Compatibility / Incompatibility of Commonly Used greases

Table Two – Different types of grease are not always compatible with each other. For instance, the first

two grease compounds, Aluminum Complex and Barium Complex are incompatible as indicated by

the “I” inside a red box. A “C” inside a green box indicates that the two compounds are compatible with

each other. A “B” in a yellow field indicates the two compounds possess only borderline compatibility.

C

= Compatible

I

= Incompatible

B

= Borderline