q

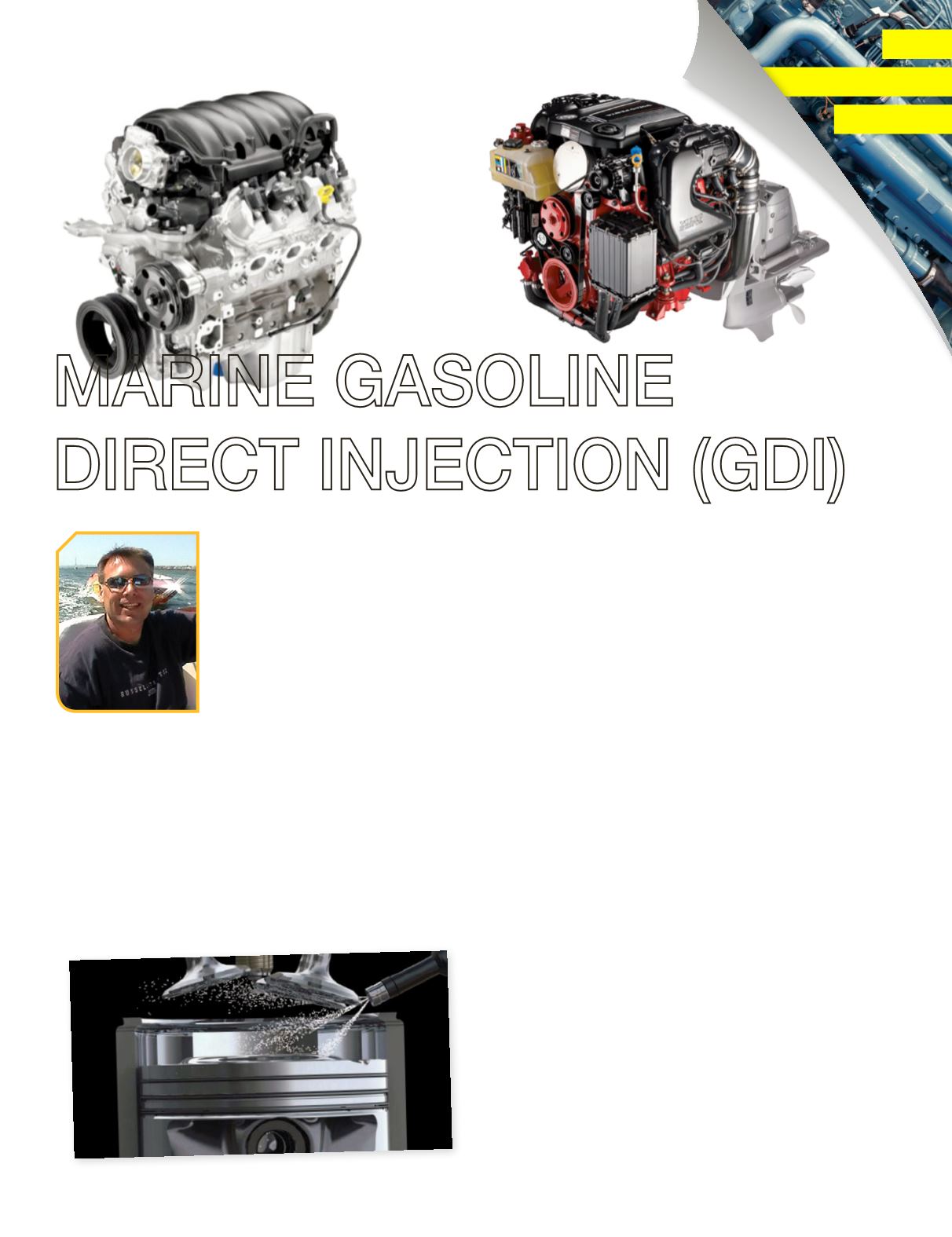

GM Marine 4.3 liter

direct injection engine

p

Volvo Penta

4.3 direct injection

240 hp engine & drive

SUMMER 2015 | MARINE TECHNICIANTODAY

19

THE

PERFORMANCE

CORNER

2

015

has proved to be a very busy

year regarding the introduction

of new technology by the

inboard marine engine and outdrive

manufactures. Volvo Penta introduced a

forward facing twin propeller outdrive for

their marine gasoline engines in February

called Volvo Penta Forward Drive (FWD).

Volvo Penta has also introduced a new

GDI engine that is a General Motors V-6,

4.3L, 262 CID all aluminum engine block, weighing 41 lbs. less than

the older cast iron block. It can turn up to a whopping 5800 RPM!

They have added strength to the bottom end and for the crankshaft

by using 6 bolt powdered metal main caps. The engine is also offered

with variable valve timing, and a hydraulic cam phaser for variable

camshaft timing. This optimizes low end torque and high end horse

power. The ignition system has 6 ignition coils near the spark plugs.

The most significant change for Volvo Penta was the move from multi-

port fuel injection to gasoline direct injection (GDI). With GDI atomized

fuel enters the combustion chamber at 2250 psi. The engine has a

compression ratio of 11:1, which until now was unheard of for a stock,

pump gas compatible marine engine. Higher compression ratios create

a cleaner fuel burn in the cylinders resulting in reduced emissions so

more energy comes from each drop of fuel.

Since 4-stroke marine gasoline direct injection engines have not been

in service until now, marine technicians need to be aware of what sort

of maintenance is needed and what problems can happen that would be

different than carbureted or EFI engines. To further investigate we need

to examine what is happening in the automotive field in regards to GDI.

GDI has been around in its current form since about 1997. When these

early direct injection automotive engines hit approximately 30,000

miles many would develop engine running problems due to carbon

build up on the necks of the intake valves. Typical symptoms were

misfire codes, rough idle, stumbling and fuel trim problems. Carbon

deposits caused the incoming intake air to tumble into the combustion

chamber and this turbulence caused uneven distribution of the fuel

& air mixture. When ignited, the flame front can be erratic leaving

unburned fuel and create hot spots in the combustion chambers. This

brings the question, why are direct injection engines prone to carbon

deposits? The main reason is that the fuel, specifically the detergents

in the fuel, are no longer passing by the intake valves keeping them

clean of deposits. Remember, there is no longer any fuel passing

through the intake manifold, only air. The fuel is injected directly into

the combustion chamber. Another issue causing the problem is the

higher compression ratios of these engines. Higher compression ratio’s

cause higher combustion pressures, and direct injection engines have

leaner air to fuel ratios, making carbon deposits worse over time.

A GDI engine produces more energy from a given amount of fuel and

air than a multi-port fuel injected engine. Marine GDI engines, especially

ones run on poor quality fuel or ones that are poorly maintained can be

operating on the ragged edge of running lean or misfiring. When a cylinder

does not fire properly, combustion by-products are left in the cylinder.

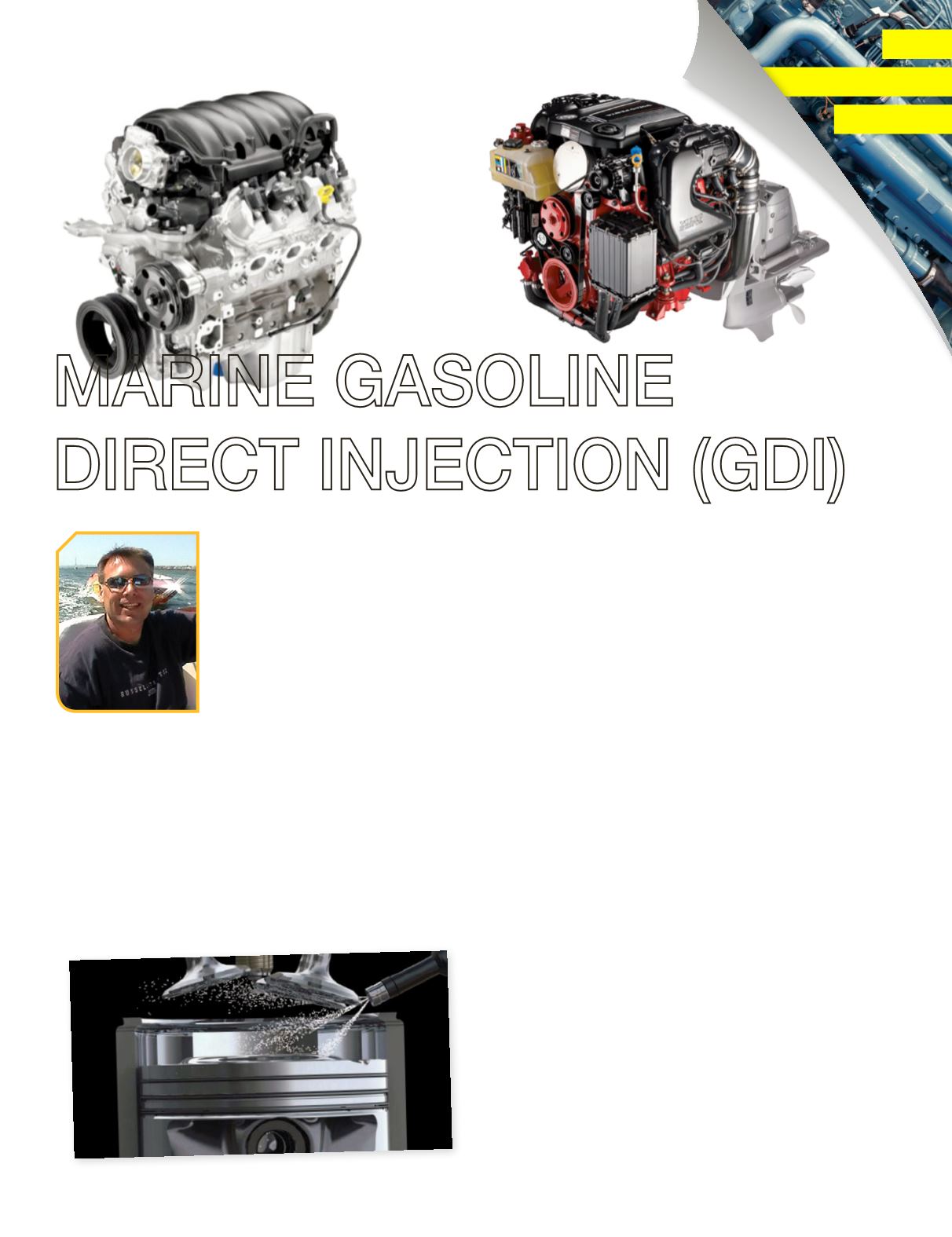

p

Direct injector spraying fuel into combustion chamber

MARINE GASOLINE

DIRECT INJECTION (GDI)

By John Mosetti