Winter 2015

NCRWA.COM11

feature

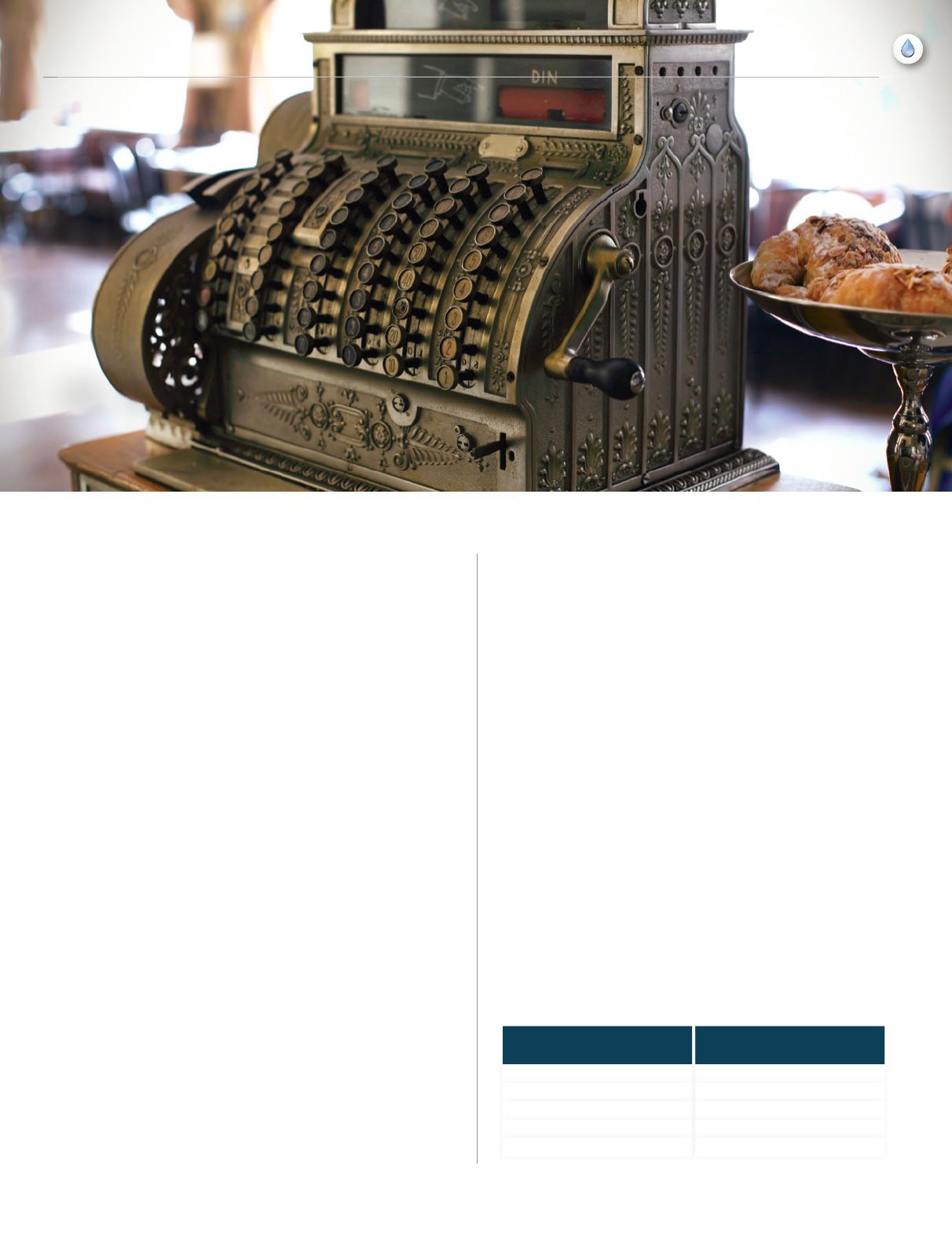

T

he water meter has always been thought of as a water utility’s cash

register. But just as a meter helps you properly charge for water use, a

poorly maintained or worn water meter can actually lose you money.

Save your system money and water by keeping your meters in good

repair and by implementing a meter change out program.

To adequately maintain your meter you must first understand how they

work. The most common water meter used for residential customers is

the positive displacement (PD) meter. PD flowmeters measure fluid flow

by precision fitted gears or rotors as flow measuring elements. These

elements have known and fixed volumes that are displaced between the

gears and the rotation of the rotors are proportional to the volume of

the fluid being displaced. These meters work well with viscous fluids

or other fluids with little to no straight run requirements. Two common

methods of positive displacement measuring are Oscillating Piston

meters and Nutating Disk meters. Both methods rely on the water to

physically displace the moving measuring element in direct relation to

the amount of water that passes through the meter. The piston or disk

moves a magnet that drives the register.

PD meters are generally very accurate at low to moderate flow rates

typical of residential and small commercial users, and are common

in sizes from 5/8 of an inch to two inches. Because displacement

meters rely on all water flowing through the meter to “push” the

measuring element, they generally are not practical in large commercial

applications requiring high flow rates or low pressure loss.

Positive Displacement meters normally have a built-in strainer to

protect the measuring element from rocks or other debris that could stop

or break the measuring element. PD meters normally have bronze, brass

or plastic bodies with internal measuring chambers made from molded

plastics and stainless steel. Often brass meters contain anywhere from 5

to 40 percent zinc, which is added for tensile strength.

A positive displacement meter is an accurate way to measure water

flow for your customer but, as is the case with anything with moving

parts, they can wear out. As the meter wears out, it is always to the

customer’s advantage. Meters will usually not read higher but instead

will read lower, thus increasing water loss and a loss of money for the

water system. A good rule of thumb on a meter change out program is

to replace your meter after 10 years or a million gallons, whichever

comes first.

For example, let’s assume a household uses 6,000 gallons a month and

your water system charges $3.00 per thousand gallons. If your water

meter is reading 85 percent, this would result in a loss of $32.40 a year

for this household. Multiply that by the amount of customers you have

and the losses in your revenue can be quite significant.

Other ways meters are losing revenue for water systems are not using

the meter equivalents set by the American Water Works Association

(AWWA). These have been an industry standard for many years;

however, some systems charge one base rate for all meters regardless

of meter size.

feature

By Jesse Miller, Circuit Rider, SCRWA

IS YOUR CASH REGISTER

WORKING PROPERLY?

5/8 x 3/4

3/4

1

1.5

2

1

1.5

2.5

5

8

METER SIZE IN INCHES AWWA METER EQUIVALENT