SPRING 2015 | MARINE TECHNICIANTODAY

19

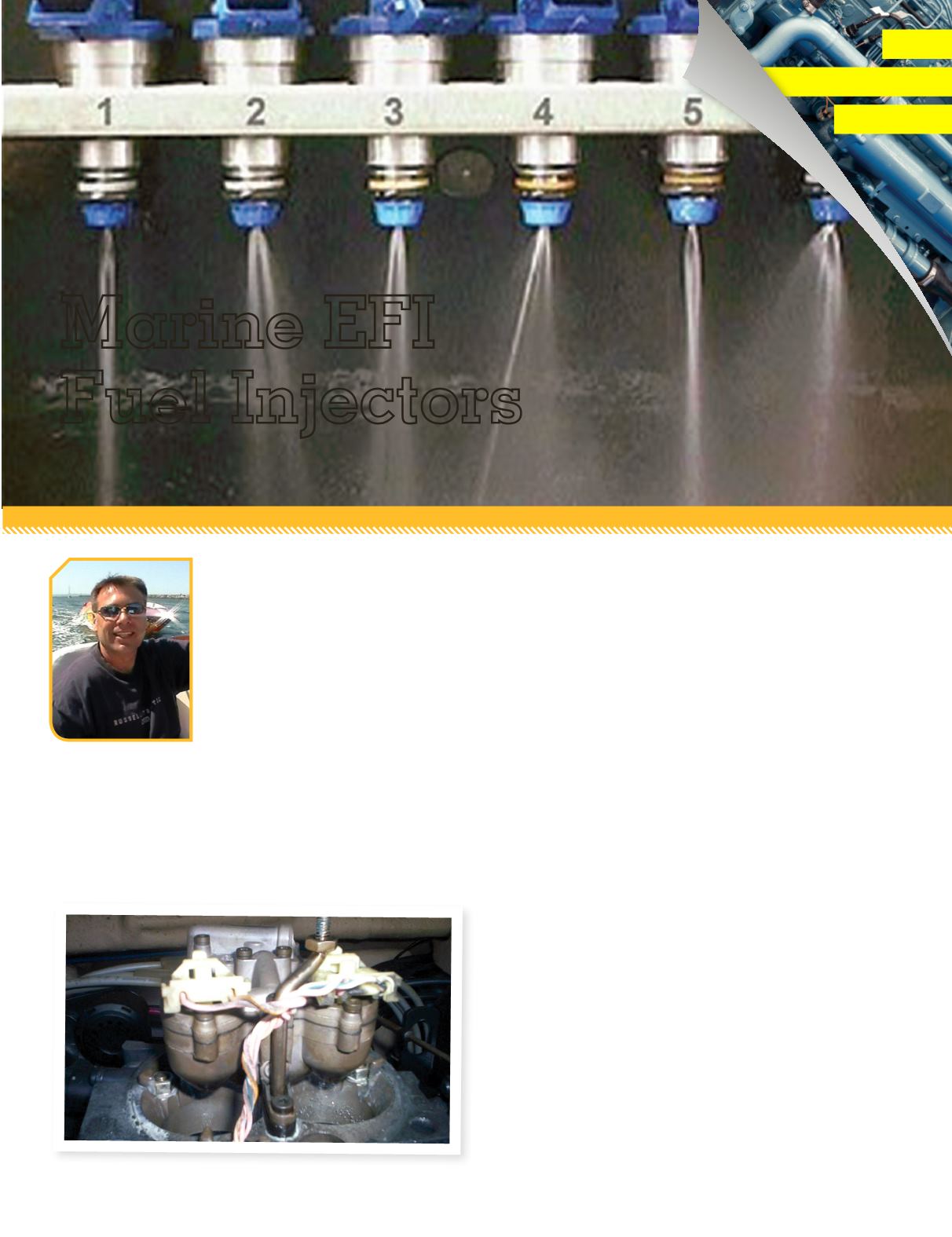

Marine EFI

Fuel Injectors

N

o one ever said that solving really

tough fuel injection problems was

going to be easy, nor is it easy to

keep up with all the new technology coming

out right now. Volvo Penta offers direct

injection for 2015 on the new 4.3 L GM Gen V

foundation aluminum blocks, and MerCruiser

is now building their own 4.5L V-6 engine.

The old standby marine engines are gone or

going away very soon. General Motor’s 4.3L

engine is already gone, next on the list to get

the axe are the GM 5.0L and 5.7L engines. Soon to replace those aging V-8’s,

Volvo Penta will be offering a 5.3L GM based direct fuel injection engine,

and MerCruiser will have a V-8 engine, all assembled in house at the factory

in Fond-du-Lac, WI. To add to that, Ford has thrown its hat back into the

marine market and is offering a marine application of its 6.2L Raptor engine

marinized by Indmar along with collaboration with Roush Racing. This new

technology is significantly more advanced than the traditional EFI marine

engines currently offered and may prove to be quite challenging to repair,

especially for the marine technician who is not up-to-date with current EFI

and catalyst systems.

With that said, this article will focus on how the EFI systems fuel injector

works. Since EFI engines have been out for many years now, it appears

that the actual fuel injector is starting to become a more common fault of a

poorly running engine. They fail electrically, mechanically, or become partly

or fully restricted. Currently there are two basic styles of injectors used in EFI

engines, one style for TBI (Throttle Body Injection) and MPI (Multiport Fuel

Injection) systems.

The TBI system uses a throttle body assembly as a base (looks similar to a

carburetor) for the mounting of 2 or 4 injectors mounted above the throttle

body’s venturi. Besides the injectors, the throttle body contains the throttle

plate, fuel pressure regulator, IAC valve (Idle Air Control) and the TPS (throttle

position sensor). The TBI injector is a solenoid operated valve that is turned

on and off by the ECM. The injectors operate off of 12 VDC, usually supplied

by an ignition / fuel relay. Drivers in the ECM supply the ground to the

negative terminal of the injector to actuate the solenoid valve inside.

Energizing the injector’s solenoid opens a ball valve allowing pressurized

fuel to flow through a flow director plate containing 6 machined holes. This

creates a conical pattern of finely atomized fuel that is sprayed into the TBI’s

venturi. TBI systems fire one injector on one Ref Hi signal and the second

injector on the next Ref Hi signal.The injectors only fire one time per complete

firing cycle of the engine. The injector supplies fuel for several cylinders each

time it is fired. The intake manifold is wet with fuel, just like the manifold

of a carbureted engine. The amount of fuel injected is determined by the

length of time that the injector is energized, this is called Pulse Width. The

ECM calibration is based on the fact that an injector discharges a known

amount of fuel per millisecond at a specific pressure. Maintaining proper

fuel pressure and flow is essential to providing the correct air to fuel ratio

for all running parameters. NOTE: never apply battery voltage to the injector

terminals for testing as the internal solenoid may become damaged in a

matter of seconds.

THE

PERFORMANCE

CORNER

By John Mosetti

u

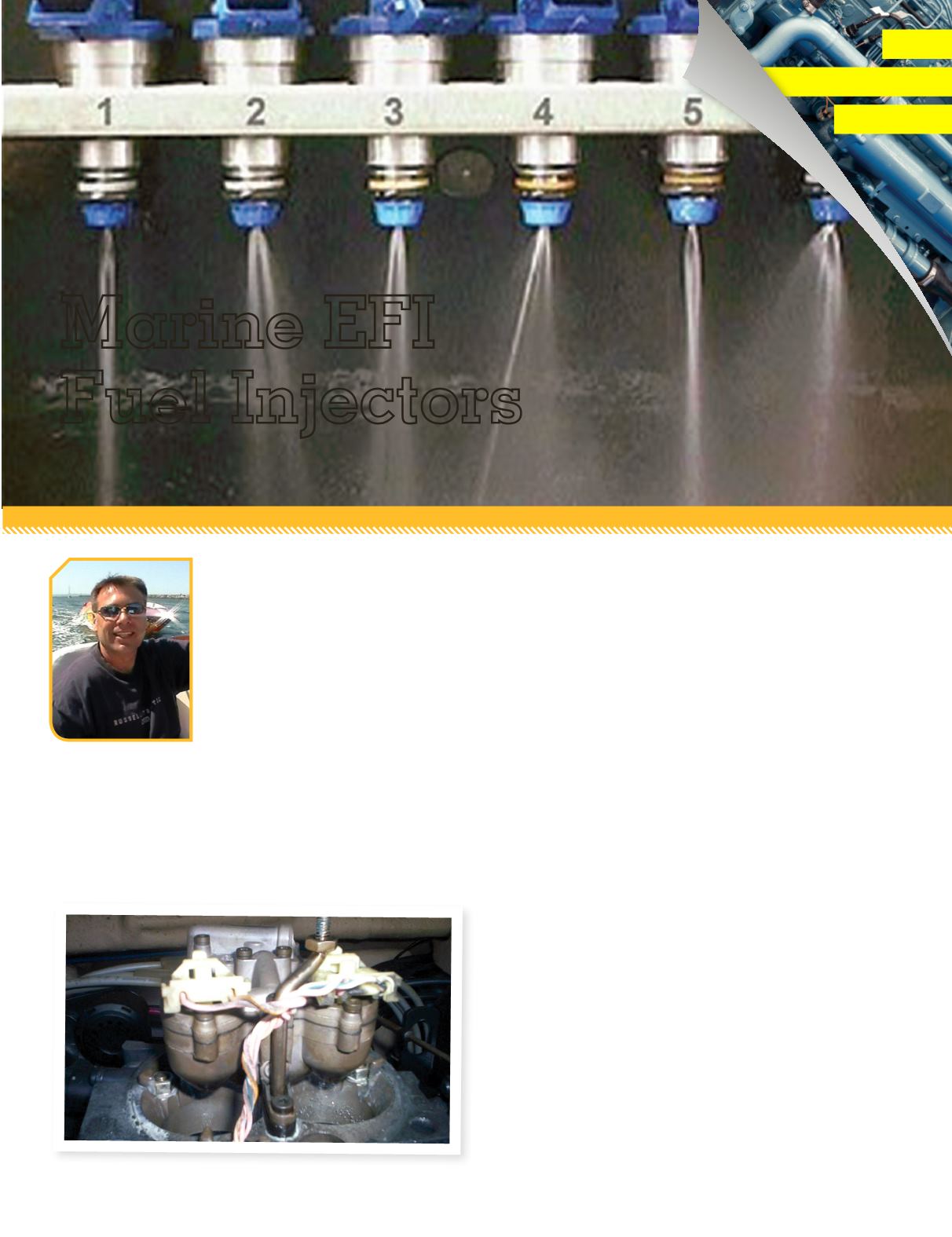

TBI throttle body injection poor spray patterns