SPRING 2015 | MARINE TECHNICIANTODAY

15

A

s every boat owner or repair

technician knows, the horror of

hearing the outdrive grind to a halt

and seize is a gut-wrenching experience.

Not only can you be stranded, but you know

it is one of the most expensive repairs that

can be done on your boat. Outdrives are

truly a work of art with precision gears

and top of the line bearings. These gears

transfer tremendous power from the

engine to the prop and they are under

extreme load and many times at high RPM. At any moment the prop

can hit submerged objects that can transfer high shock loading in the

gear set. The most critical factor in the life of the gears and bearings

is the lubrication provided by the gear oil in the casing. In this article

I will explain the functions and properties of gear oils and how they

provide lubrication.

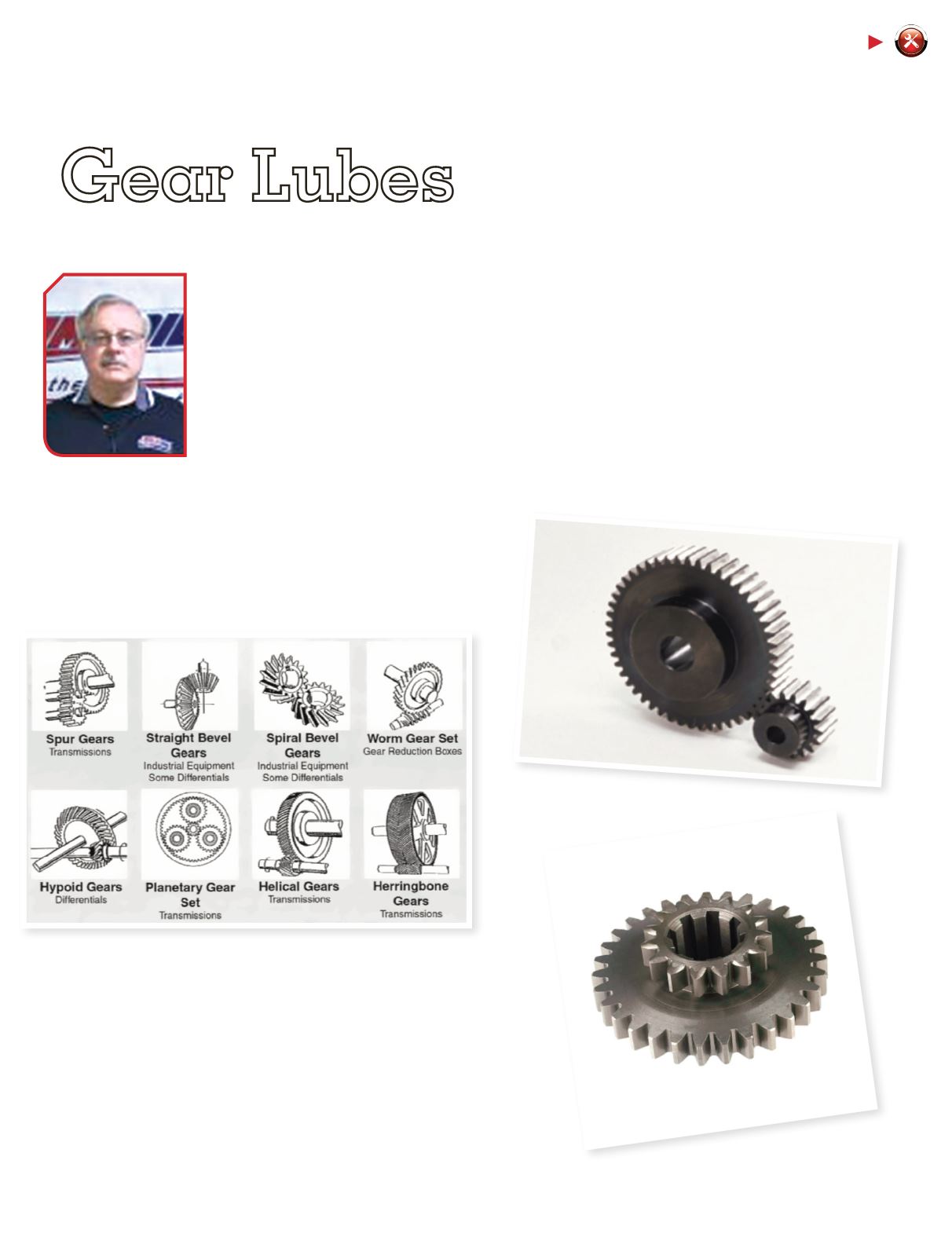

Figure 1

First, a little knowledge of gears is important to understanding the

nature of gear lubes. Refer to Figure 1 for this discussion. Gears

transmit motion and power from one rotating shaft to another rotating

shaft providing multiple applications of power transmission. There are

several types of gears and various geometric shapes for gears, but I am

only addressing basic applications. In Figure 1 Spur gears, Bevel gears

and Hypoid gears are displayed. Spur gears are simple gears with easy

meshing gear teeth transferring power between parallel shafts. Bevel

gears allow for intersecting shafts to transmit power. Hypoid gears are

designed to facilitate transferring power between non-intersecting

shafts at right angles. The important concept to grasp in these gear

sets is the action of contact and sliding motion. The Spur and Bevel

gears are engaging and rolling in motion, where the Pinion and Ring

gear in the Hypoid gears are contacting and sliding. This sliding

action allows the Hypoid gears to transmit greater power (the force is

distributed over the sliding area) providing for smaller differentials in

auto and truck applications.

By DanWatson

TECH TALK

Gear Lubes