16

MARINE TECHNICIANTODAY | SPRING 2015

With this limited intro to gears, we can now go forward with the design

and function of gear lubes. Gear lubes must achieve the following (in no

particular order):

• Provide for proper shifting in manual transmissions in

all temperatures

• Maintain fluid separation of moving metal surfaces

• Reduce friction and wear

• Lubricate associated bearings

• Prevent scoring of highly stressed gears

• Provide fluid flow in cold temperatures

• Remove heat during operation maintaining safe temperatures

• Demulsify (separate from water)

• Prevent rust and corrosion

• Resist foaming and dissipate entrained air bubbles

• Be compatible with all seals

Gear lube is a complex product accomplishing a multitude of functions,

and if any of these functions are ignored, it can result in damage to

the components. The American Petroleum Institute (API) establishes the

service classifications for gear lubes as follows:

GL-1 through GL-3: Light loads on spiral and bevel gears usually satisfied

by motor oil.

GL-4: Designates the type of service characteristics of gears, particularly

hypoid in passenger cars and other automotive equipment operated

under high speed, low torque, and low speed, high torque conditions.

GL-5: Designates the type of service characteristics of gears, particularly

hypoid in passenger cars and other automotive equipment operated

under high speed, shock load; high speed, low torque, and low speed,

high torque conditions.

The Society of Automotive Engineers (SAE) establishes the system to

classify gear lubes by viscosity grades. The exact values for the viscosity

grades is beyond the scope of this article; however, understanding

the designation and what it means is important. Gear Lubes use a

designation such as 75W-90 to indicate the viscosity grade. The 75W is

the winter rating and establishes the cold weather performance of the

lubricant. The 90 is the operational viscosity and is measured at 212*F

(100*C). The smaller the W number the better the lube oil functions in

cold weather; the larger the second number the more viscous (thicker)

the oil.

Manufacturers stipulate the required GL and SAE classifications for a

particular gear set. The recommendation is based on the geometry (spur,

bevel, hypoid, etc.), loading and environment.

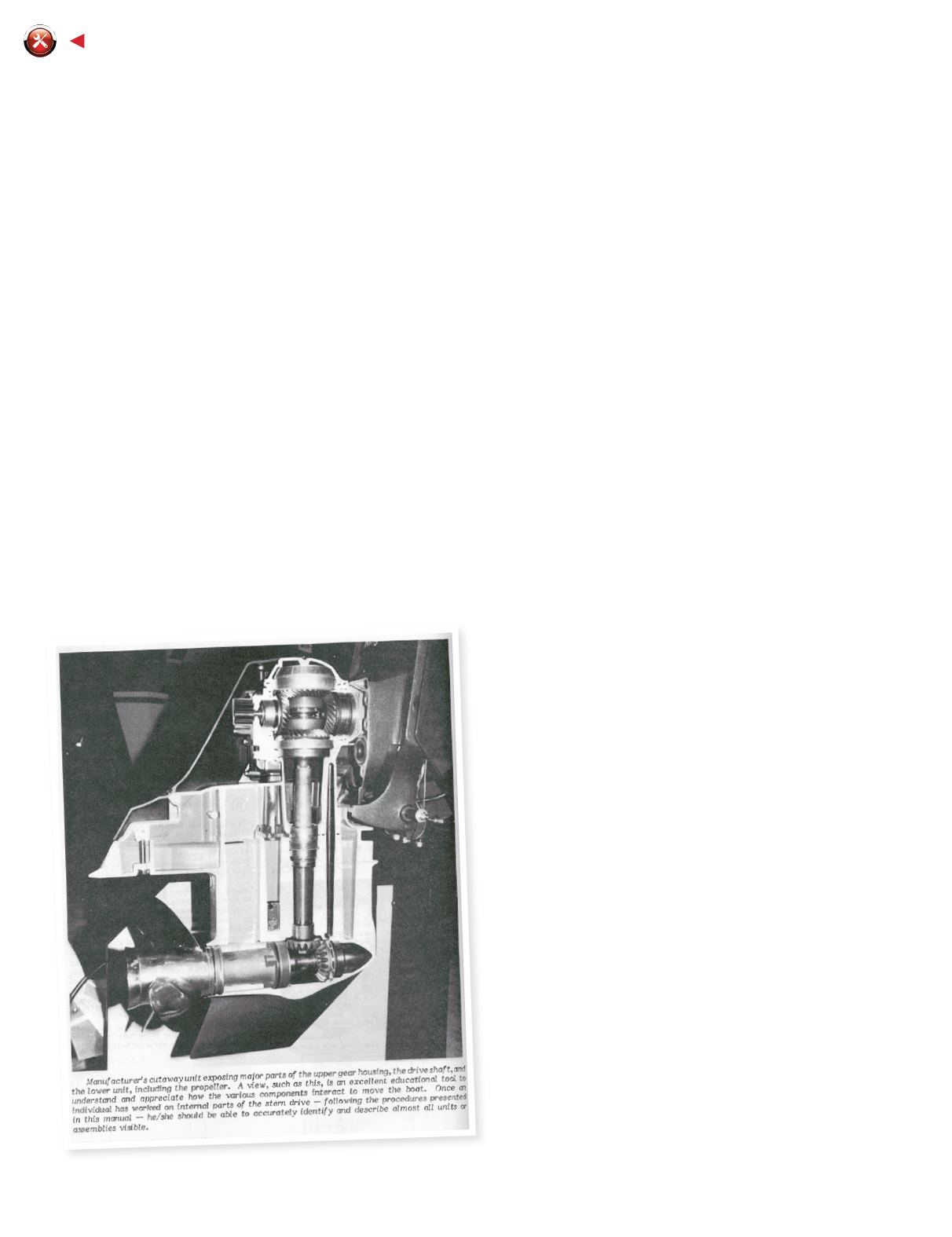

Marine applications usually come down to transmissions and outdrives.

Materials used in the construction of the components (brass compounds)

can require different types of additives in the gear lubes.

Gear Lubes are formulated by selecting base oils from petroleum or

synthetic oils and adding in specific chemicals to achieve the rated

classification. The additives consist of anti-wear, anti-foaming, anti-

oxidation, demulsifiers, corrosion inhibitors, friction modifiers, viscosity

improvers and extreme pressure additives and specialty additives where

required. The specific formulations are determined by the manufacturer

and all gear lubes are not created equal.

Original Equipment Manufacturers (OEMs) determine the required gear

lubes for the gear sets in their manufactured products. You can find

the specified gear lube listed in the owner’s manual, and in general,

this is the gear lube you should use; look for a viscosity rating, like

75W-90 and a classification, such as GL-4 or GL-5. A classic error

made many times by consumers is to buy thicker gear lubes to get

better protection. There are times when using a 75W-140 or 75W-110

instead of the specified 75W-90 is appropriate, but that change should

only be made on the advice of a lubrication professional. The failure

rate for gears is very low, but the failure rate for bearings is not so low.

Bearings are better lubricated by thinner oils, and so the rush to put

heavy oils in the gears can result in increased bearing failures. Thicker

gear lubes provide better shock absorption at the gear face and

prevent spooning or cupping gear teeth. Under normal operation the

outdrive gear set does not require the higher shock loading associated

with heavier gear lubes. When power is applied to the prop if the rate

of application is too high, the prop cavitates and the load drops off.

In very large props the continuous load is high enough to warrant a

TECH TALK