Summer 2014

| NCRWA.COM

17

feature

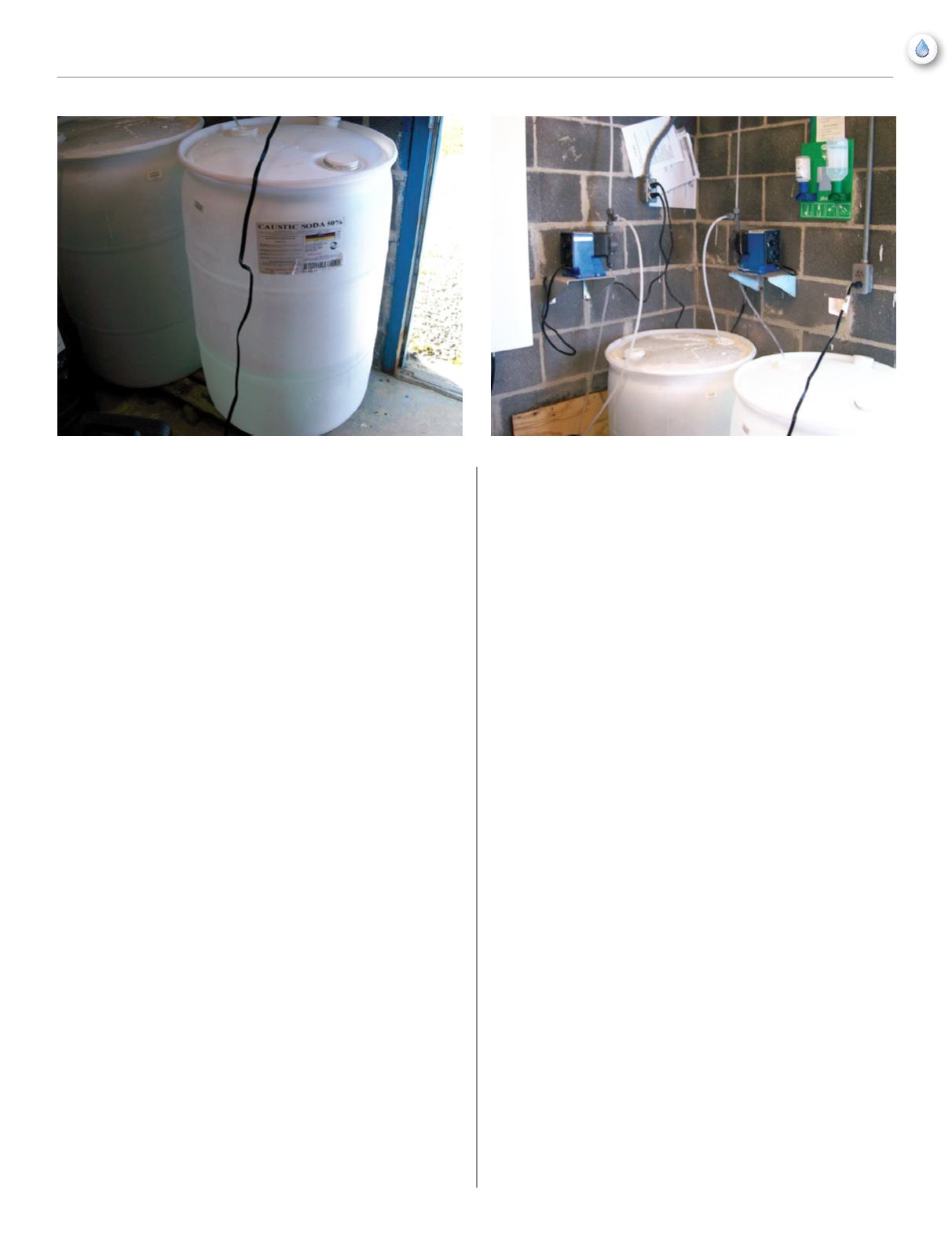

Expenses are, of course, passed on to the consumer. “As far as time

spent in achieving compliance with the rule, it took about eight months

of trial and error to obtain a good level of comfort with the injection

levels and chemical pumps.” Two to three hours per day, on average,

were spent sampling and recording to ensure that the proper levels of

injected caustic and orthophosphate were being used.

Lead and copper levels were problematic in Newland due to low

exchange of water in the distribution system and an older population

that typically does not use as much water as the average consumer

elsewhere. To begin to comply with the Rule, the oldest houses in the

system were selected as sampling points, and consideration was given

to maximum residence time of water in the mains. Worst case scenarios

were used as sampling points. “Ever since I’ve been here we’ve had a

problem” said Mr. Hoilman. “The State mandated bi-weekly testing for

a year at the well site. All samples were sent to certified laboratories and

the cost ran to almost $10,000 per year.”

The team from Newland went to every selected site and began sampling,

and soon found that detailed record-keeping was a must to determine

the proper amount of chemical to inject at the wellhead. Water samples

were taken near the wellhead in five-minute increments up to 30 minutes

during the initial adjustment phase of chemical treatment. Because of its

success in treating lead and copper, Newland is currently on a three-year

lead and copper sampling schedule.

On one of the wells, Keith had a mixer installed in the distribution main

near the wellhead to ensure that orthophosphate, caustic, and chlorine

is mixed thoroughly. After the mixer, a tap near the well house is used

for drawing samples as soon as the water enters the distribution system.

This considerably eased the sampling procedure, and made it easier

achieve compliance with the Rule. Keith also found that keeping a

detailed log for each chemical injection pump decreased the trial and

error that would have been encountered had no records been kept.

Newland got a lot of help and advice from the Asheville Regional Office

Public Water Supply Section, from Jim Adams and Bill Conners. The

Public Water Supply Section Regional Engineer can offer real-world

assistance in implementing a good corrosion control program.

Other adjustments in the injection system included positioning the

injector quill in the direct center of the pipe, to ensure thorough mixing

of the chemicals (NC Rural Water circuit rider Keith Buff made this

suggestion). If the quill is not centered in the pipe, water flow is not

turbulent enough to ensure adequate chemical mixing. Keith and Roger

Woods, system ORC, also had to adjust the size of the chemical pumps

to ensure the pressure was great enough to overcome head levels,

because of changes in water pressure with elevation, which sometimes

causes water to flow both ways in the Newland distribution system.

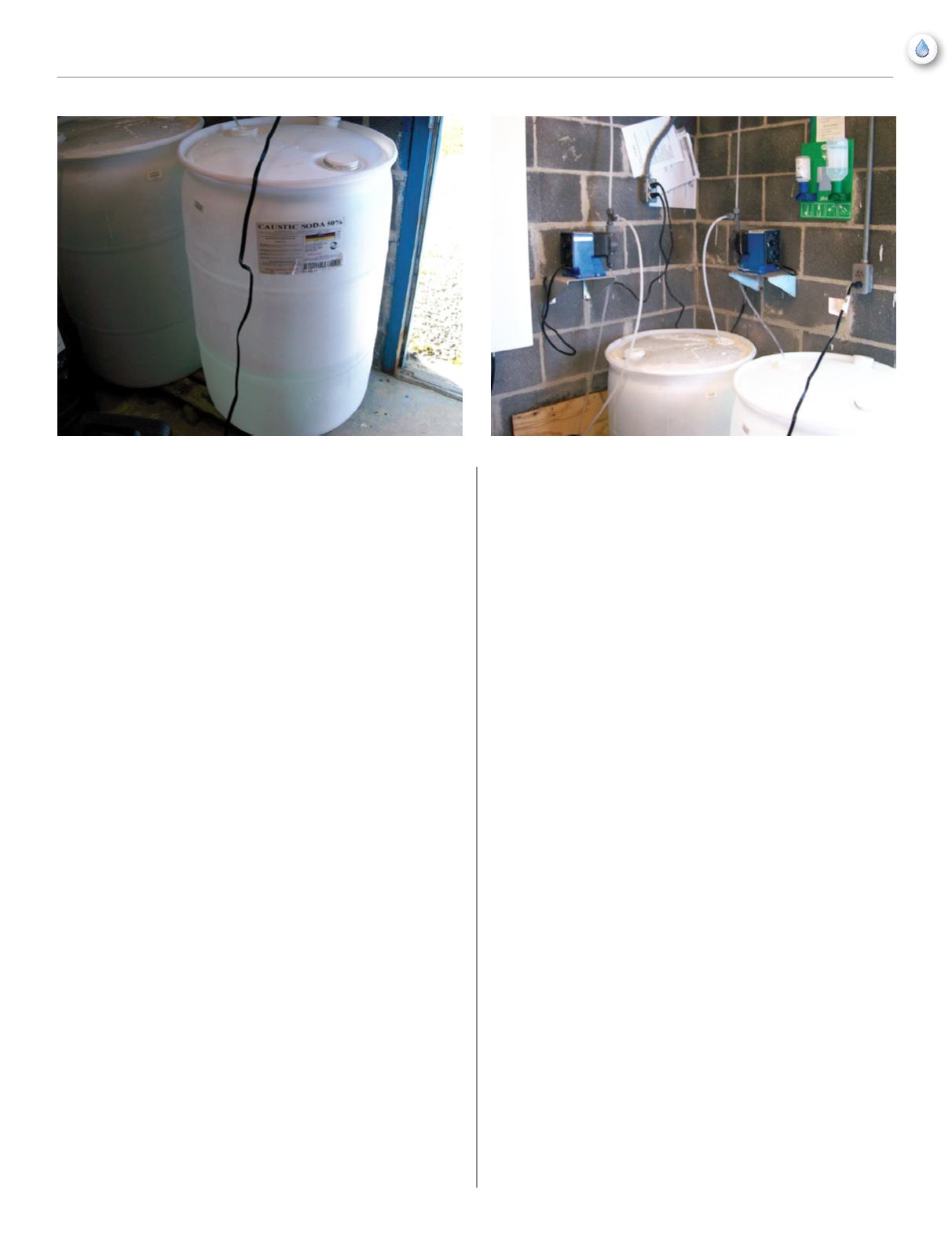

The Newland well houses are of block construction and this presented a

problem for the caustic injection. Low temperatures increase the viscosity

of the caustic solution, which will freeze at 56

o

F. Because the cinderblock

walls and concrete floor of the well house retain cold much more than the

ambient air temperature, Keith and Roger soon noticed that the pH of the

finishedwaterwouldvarywithdaily and seasonal temperaturefluctuations.

By accurate record-keeping, they came to the conclusion that the cold

walls and floor of the well house were preventing consistent injection of

the caustic because of increased viscosity at lower temperatures. To solve

this problem, the drums were elevated on a wooden blocks to get them off

the cold floor of the well house. Heaters were installed to keep the well

house and caustic at a controlled temperature.

Using caustic can be very dangerous. Proper handling equipment is a

must, and this includes eye protection, gloves and bibs, and each well is

equipped with these, as well as an eye wash station in each well in case

of accidental spills. A vinegar solution is also located in the well houses

to neutralize the caustic if it splashes into eyes or on skin.