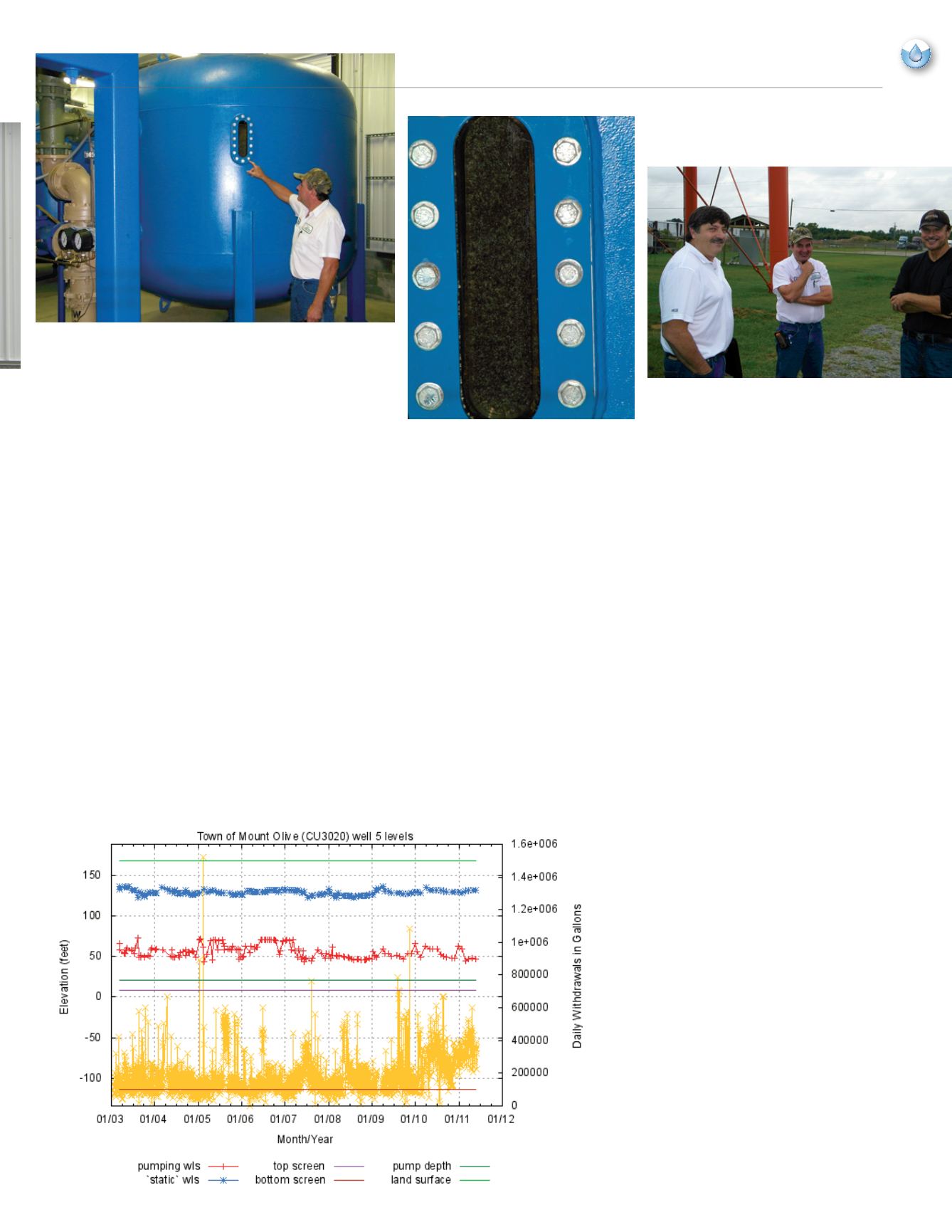

Figure 1 shows a hydrograph for Mount

Olive’s #5 well. Static water levels shown

in blue are steady across the graph, over

a period of more than ten years. This

indicates a healthy aquifer with adequate

recharge. The pumping water levels over

the same time period are also steady, and

this shows that the well’s pump and gravel

pack are functioning as designed. Keeping

track of static and pumping water levels is

important to gage how the aquifer, well and

pump are performing.

FIGURE 1.

HYDROGRAPH OF MOUNT OLIVE WELL 5

The Town obtained a combination grant

and loan from the State Drinking Water

Revolving Fund to expand the water

treatment facility located on Boiling Chair

Road in order to improve the quality of

the drinking water. The entire project was

initially approved for $2.2 million with

80% of the total being grant money, and

20% matching funds. Mt Olive Pickles

quickly agreed to partner with the Town

to assist with the matching funds, because

of its vested interest as a groundwater

stakeholder. The Town ended up owing

about $434,000 toward the project.

One thing that helped the Town obtain a

grant through the revolving fund was their

state-approved Wellhead Protection Plan.

When applying for a grant or loan through

the State Revolving Fund, preference points

are given for having an approved wellhead

protection plan. Wellhead protection is a

way that water systems can protect their

source aquifer from surface spills or leaks

that can enter groundwater and be drawn

into the cone of depression of a pumping

well. Mount Olive used public education

to increase awareness of best management

practices to reduce the chances of leaks or

spills within its wellhead protection area.

NC Rural Water Association can assist

your groundwater system in developing a

wellhead protection plan at little or no cost

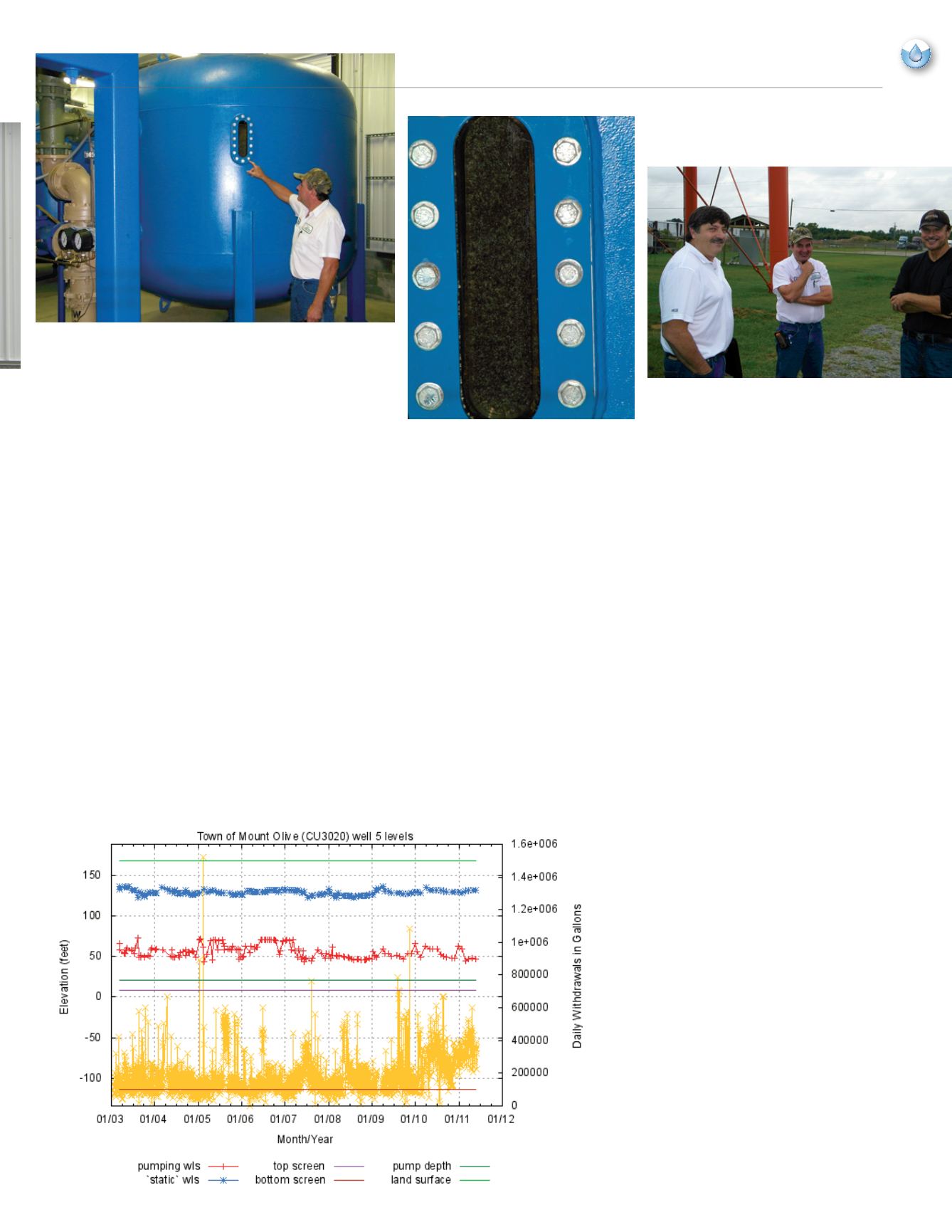

A common treatment for iron in

concentrations up to 10 or 15 mg/L is a

manganese greensand filter. Mount Olive’s

old water treatment plant used four large

glauconite greensand and anthracite media

filters to remove iron down to levels of

0.2 to 0.3 mg/L. The ferrous iron in the

raw water was chemically oxidized by

chlorine injection, causing precipitation,

followed by filtration through the media in

the pressure vessels to remove the iron and

manganese. The old filtration system used

52,000 gallons for each backwash, which

Red and White during backwash

Site glass in tank so filter medium

can be seen during run time, a

requirement by Public Water Supply

Winter 2014 |

NCRWA.COM

29

feature