starting of backwash

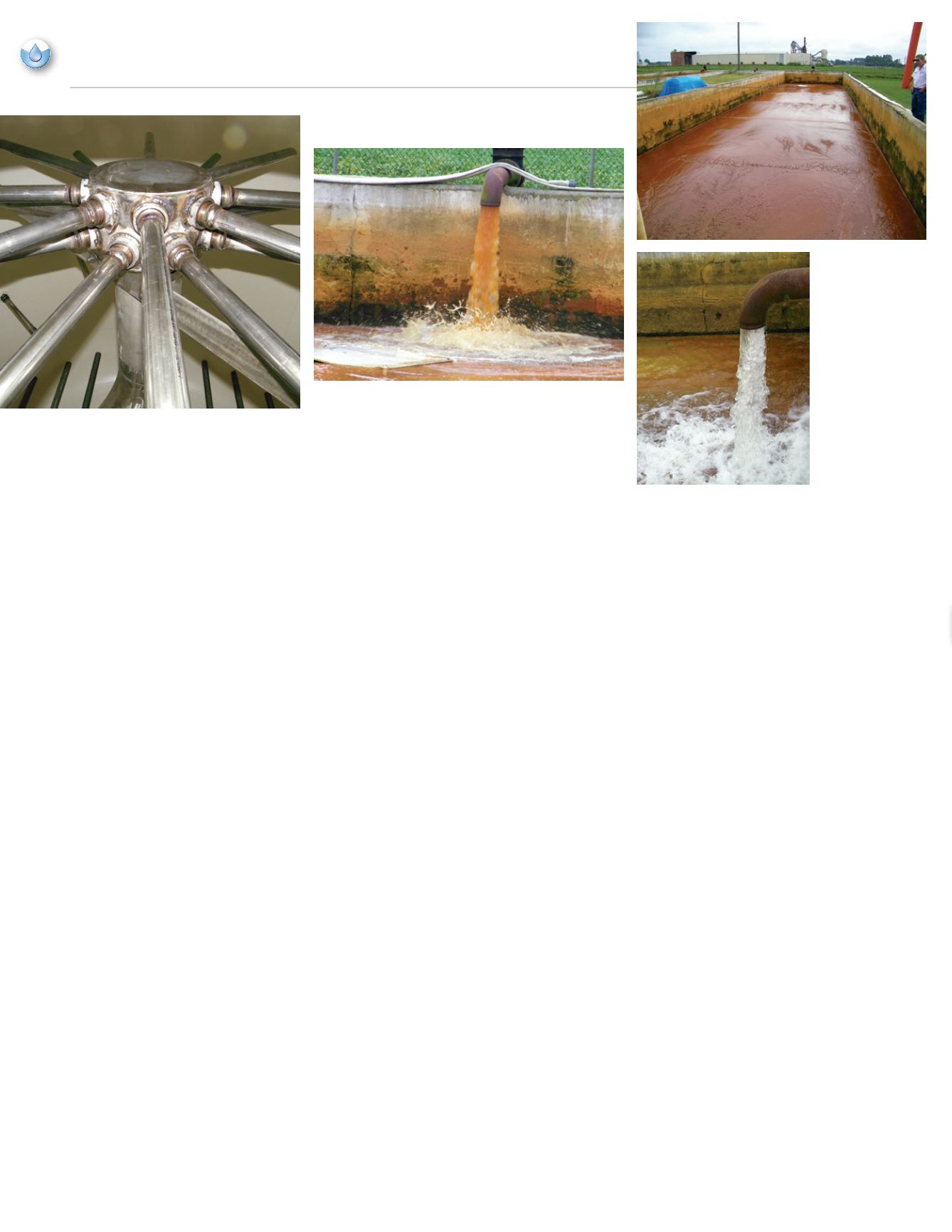

end of backwash

30

NCRWA.COM |

Winter 2014

feature

had to be performed daily. Drying beds at

the side of the plant receive the backwash,

which is later disposed of by piping to the

Town’s wastewater treatment plant.

McGill Associates was the engineering

firm responsible for designing the water

system upgrade, and the Mount Olive

water system is the first in the state to use

this technology. Boiling Chair WTP was

selected as the site for pilot testing for the

new filter media to remove colloidal and

ferrous iron and manganese. A single large

pressure filter vessel with red and white

sand filter media was installed several

months ago, replacing an old greensand

filter. Testing soon began on determining

optimal filter loads and run times. After

the initial pilot test results are confirmed,

the plan is to replace one of the three

remaining greensand and anthracite filters

with a new pressure vessel filled with red

and white sand filter media each year. The

new pressure vessels are equipped with a

sight glass on the side so the operator can

view the condition of the sands.

Spencer Bush of WaterEngineering of

Cassatt, South Carolina explained the

advantages of his company’s red and white

sand filter media. “No filter media works

here for long runs because of the high iron

content in the raw water. Colloidal iron

is also a problem here and is difficult to

remove”. Colloidal iron is a very fine solid

particulate material (typically between 0.1

and 0.001 microns in diameter) which,

when suspended in water, can neither be

settled nor filtered. The new filter media

are expected to increase run times, more

effectively reduce ferrous and colloidal

iron in drinking water, and decrease the

volume of backwash.

The chemical nature of the sands is

proprietary information, but Mr. Bush

explained that the sands are naturally-

occurring minerals which appear to be

composed of rectangular equi-dimensional

grains. A jar of the sands is really heavy,

showing a high specific gravity. The white

sands also have a catalytic property that

helps remove colloidal iron.

The new filters are consistently producing

iron levels in the finished water of about

0.01 mg/L. The run times on the filters

have increased from one day to three days

and the volume of backwash water has

been reduced. The so far successful pilot

test has shown very positive results and full

implementation of the project is expected.

Mr. Charles Brown, Town Manager and

Mr. Deems Blanton, Water superintendent

said they had to provide more water for

Mt. Olive Pickles. At first they tried to

run the filters with just the red and white

sand, but had to go back and add caustic

soda to bring the hardnes down for the

pickle plant.

Mt. Olive Town Clerk, Mrs. Arlene G.

Talton, has been with the town for 50 years.

I am not going to tell her age because is it

not nice to divulge such information. Mr.

Maylon Weeks worked for the town 50 years,

and has since passed away. We are dedicating

this article to Mr. Weeks and Mrs. Talton for

their commitment to the town.

Mt. Olive is the first in the

State to use a new water

treatment technology with red

and white sand filtrations. The

Town’s water system has 69

miles of distribution lines, and

has a finished water storage

capacity of 1.5 million gallons.