to mark the height restrictions. To speed soil removal, the

company had custom-designed, small excavation bins

imported from Europe that could hold more than a typical

clamshell (four cubic yards vs. two cubic yards, doubling the

excavation production).

With worker safety a primary concern, the four new loaders

Goldin & Stafford ultimately purchased included scrubbers to

clean the exhaust and keep the work environment safe from

equipment exhaust fumes. Hensel Phelps also set up large

fans that were designed by a mine ventilation engineer and a

flexible temporary ductwork system to produce constant fresh

air and ensure consistent air circulation in the confined space.

The fans also included silencers to substantially reduce the

noise they generated while running constantly and providing

330,000 cfm of air to the below-grade spaces.

Once excavators dug down to the floor levels, concrete

contractor Baker DC, LLC installed a three-inchmud slab to act as

aworking surface for installationof the requiredelementswithin

the two-foot-thick below-grade floor slabs. Steel subcontractor

Canam/LPR then installed two-inch-thick steel plates with

nine-inch-long nelson studs around all slab openings, such as

elevator, stair and mechanical shafts. The plates were welded

together after their size and orientationwere confirmed tomeet

the structural design specifications. Canam/LPR also installed

wide flange beams between many columns.

After all the structural steel was installed, Baker DC installed

two layers of reinforcing steel (#8 rebar in both directions,

spaced 1 foot apart). Additional reinforcing steel elements

were installed around the embedded beams and at the steel

plate locations. Finally, Baker DC placed the 24-inch-thick

concrete structural slabs.

“Our challengewas placing over 39,000 cubic yards of concrete

and installing approximately 4,000 tons of reinforcing steel

over an 825,000 square foot area using the top-down method,”

said Richard Williams, Baker DC’s senior project manager.

“During the winter we were faced with cold weather and a

lack of direct sunlight. This retarded the concrete set time even

with added accelerators. Crews often worked 14 to 16 hours to

make sure the job was completed to the strict specifications

for floor flatness and levelness.

“We were also challenged with equipment as conventional

gas-powered equipment was prohibited. We used all-electric

equipment or placed scrubbers on the diesel equipment that

was permitted as air quality was constantly monitored for

optimal working conditions,” Williams said. “Each co-worker

was assigned an air monitor and oxygen tanks and we

implemented the buddy system where a minimum of two

co-workers would be assigned to tasks so they could keep an

eye on each other.”

For Cleveland Construction Inc. the hardest part of working

below grade was getting the material into the building. The

company installed all of the below-grade drywall plus the

drywall for the atrium facade, which extends from the hotel

lobby all the way up to the skylight. “We coordinated between

Hensel Phelps and our supplier to boom it down by crane,”

said Dave Huff, general manager. “We brought our suppliers

in between 4:00 and 5:00 a.m. to beat traffic and to get our

materials in before the day started.”

The company’s crews worked on the framing and installation

of mold-resistant drywall for the spaces around the

mechanical equipment even as the floors below were still

being excavated. “We were framing away and the dirt was

flying right past us,” said Huff.

Keeping the complicated project on schedule required close

and constant coordination between Hensel Phelps and its

subcontractors, plus long hours and many double shifts for

their workers.

BALANCING ACT

To maintain the project timeline Hensel Phelps also needed to

build above and belowground simultaneously. That presented

different challenges.

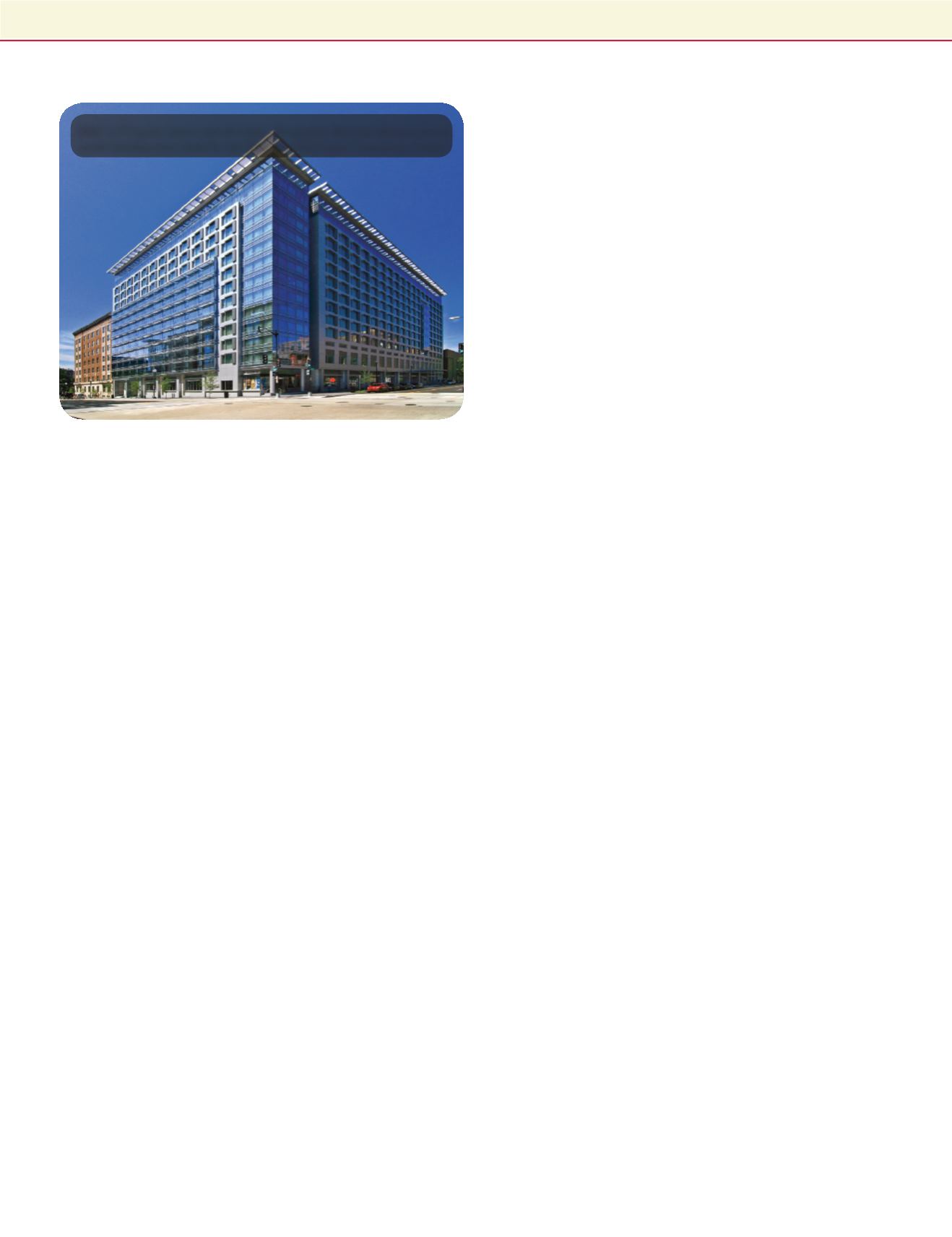

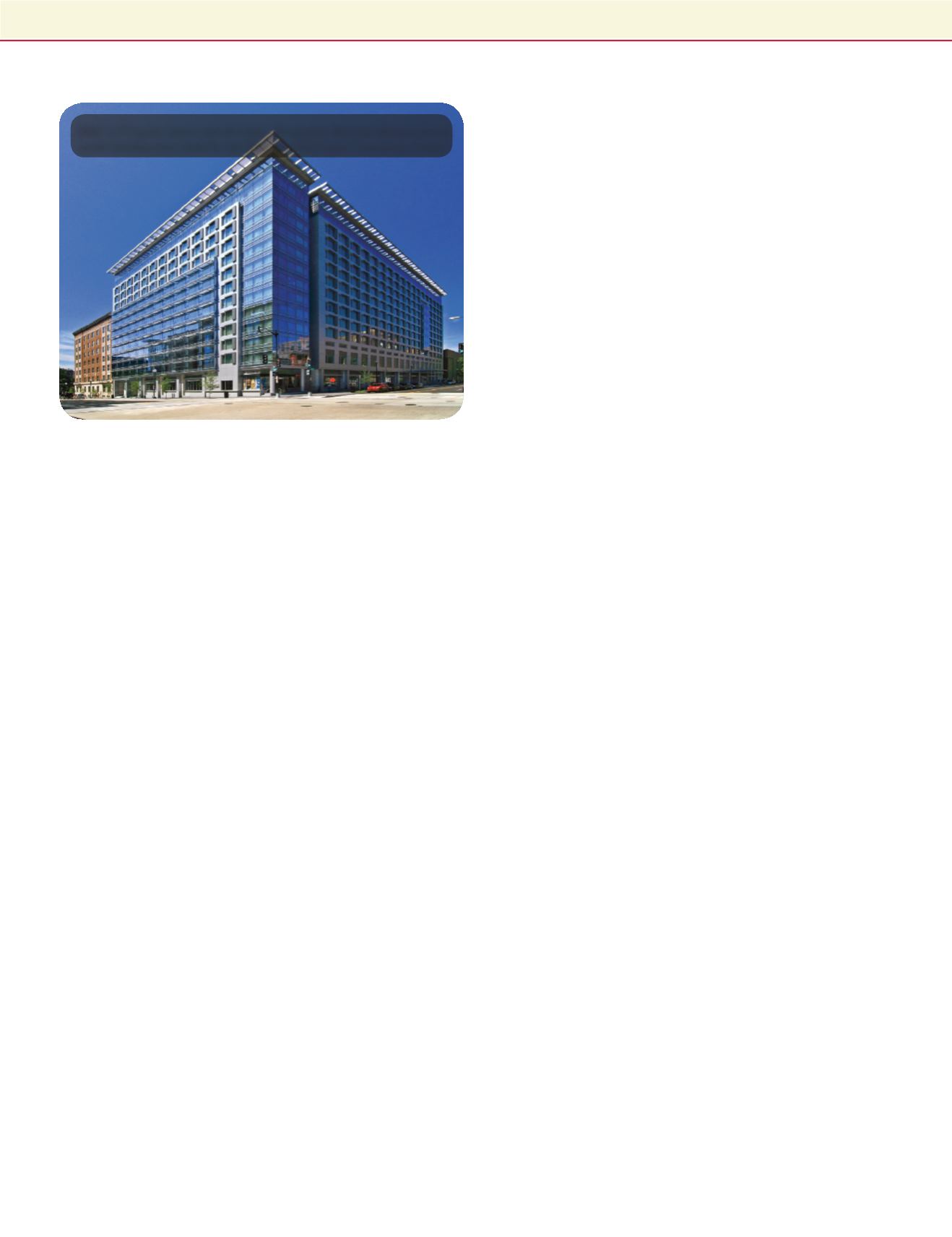

With 1,175 guest rooms and 49 suites, the upscale Marriott Marquis serves

as the headquarters hotel for the Walter E. Washington Convention Center.

10 Building Washington