32

NCRWA.COM|

Winter 2015

feature

Historically, defending data has been a time-

and labor-intensive process. Lab employees

had to collect data from dozens of different

sources—including the handwritten notes

of other staff members—to build a case in

support of a disputed result. Even today,

many labs spend as many as 10 hours a week

manually collecting and managing data. This

represents a lot of time spent on manual and

labor-intensive tasks and sometimes it leads

to wasted effort because those lab personnel

could be utilized for more important or

revenue-generating activities.

Fortunately,

comprehensive

data

management software makes it much

easier for today’s labs to defend their data.

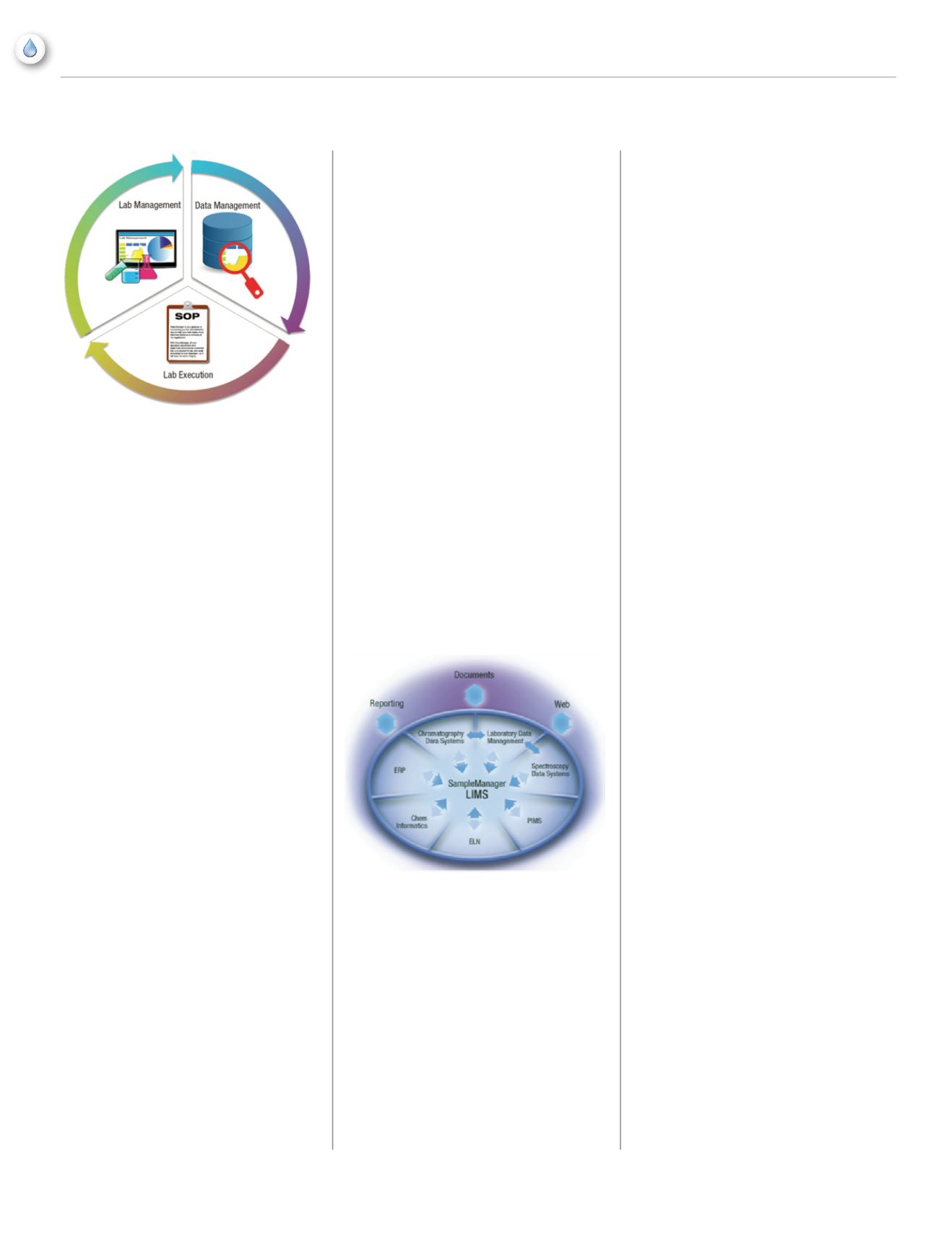

Laboratory

Information

Management

Systems (LIMS), which were first

introduced over 30 years ago as basic sample

management and data reporting tools, have

today grown into comprehensive enterprise-

level data management platforms that gather,

monitor and manage all laboratory data and

records. They also serve as the integration

point for all lab instrumentation and, in

some organizations, the electronic link to

enterprise systems such as PIMS, MES and

enterprise systems such as SAP. Having

all this data well-organized and readily

available makes the process of defending lab

results much easier, allowing lab employees

to redirect time to more productive work, and

giving management the assurance that the

lab data they’re relying on for key business

metrics is defensible.

Illustration: Gas Chromatography

Gas chromatography (GC), a common

analytical technique in water laboratories,

serves as a useful example of the sheer volume

of data necessary to support the validity of

a single lab result. In order to defend their

results, labs must account for all the variables

involved in an analysis and provide evidence

that they were executed properly. A LIMS

makes this much easier by automating the

entire data collection and reporting process.

Technical Quality

Technical quality data includes all variables

that are involved in producing an accurate

result from an instrument. A LIMS provides

an entire suite of capabilities for managing

this data and for demonstrating the reliability

of the final result.

Suppliers:

Labs require many consumables

to operate GC analyzers, from syringes to

inject samples to carrier gases that slow

the speed of the sample gases as they pass

through the column. Rather than retest all

of these consumables as they arrive at the

facility, most labs find it easier to build a

network of trusted suppliers. These suppliers

likely have a well-earned reputation for

quality which they can support with their

own laboratory data.

Transforming the lab into a tightly

integrated paperless environment gives

users real-time access to information,

automates processes and reduces manual

data handling, and improves regulatory

compliance and data integrity.

A LIMS can automate supplier data

management by helping track materials as

they enter the facility, associating them with

their supplier. If a technician needs to defend

the results from a test, she can reference the

LIMS database to verify that all consumables

used were from approved suppliers. If they

are, she can partially rule out consumables

as a fail point.

Consumable Quality: Verifying that a

consumable comes from an approved vendor

is only part of the equation. Consumables

can, after all, go out of specification during

storage or use. Fortunately, a LIMS can help

solve this problem as well: lab administrators

can configure the LIMS to trigger periodic

checks to ensure quality. Together with

verification of supplier data, this capability

can help labs avoid the inadvertent use of

out-of-specification consumables in the vast

majority of cases.

Instrument Maintenance and Calibration:

GC analyzers must be regularly maintained

and calibrated to deliver consistently

accurate results. To defend their results, labs

must also be able to demonstrate adherence

to proper maintenance procedures. Lab

managers can organize and retrieve

maintenance and calibration records by

instrument, time period, and even staff

member, directly from the LIMS, allowing

them to quickly and easily demonstrate that

an instrument in question is adhering to a

pre-defined schedule.

ALIMS adds additional value for calibrations

that require certified reference materials. In

Integrated informatics enable labs to execute and manage all

lab processes easily, with the data rigor and intelligence that

lab managers require to drive efficiency and profitability - for

the lab and for the business.

Transforming the lab into a tightly integrated paperless

environment gives users real-time access to information,

automates processes and reduces manual data handling, and

improves regulatory compliance and data integrity.