Winter 2015

NCRWA.COM33

feature

addition to tracking the calibration itself,

the LIMS can store reference material

certificates that demonstrate the quality of

the materials used.

Staff Performance

In addition to instrument error, lab results can

also be invalidated by human error. Human

errors in the lab originate from issues in one

of three broad categories: training, process

and data management. A defensible lab result

must be able to demonstrate that the lab staff

that produced it did not inadvertently make

errors in any of these areas.

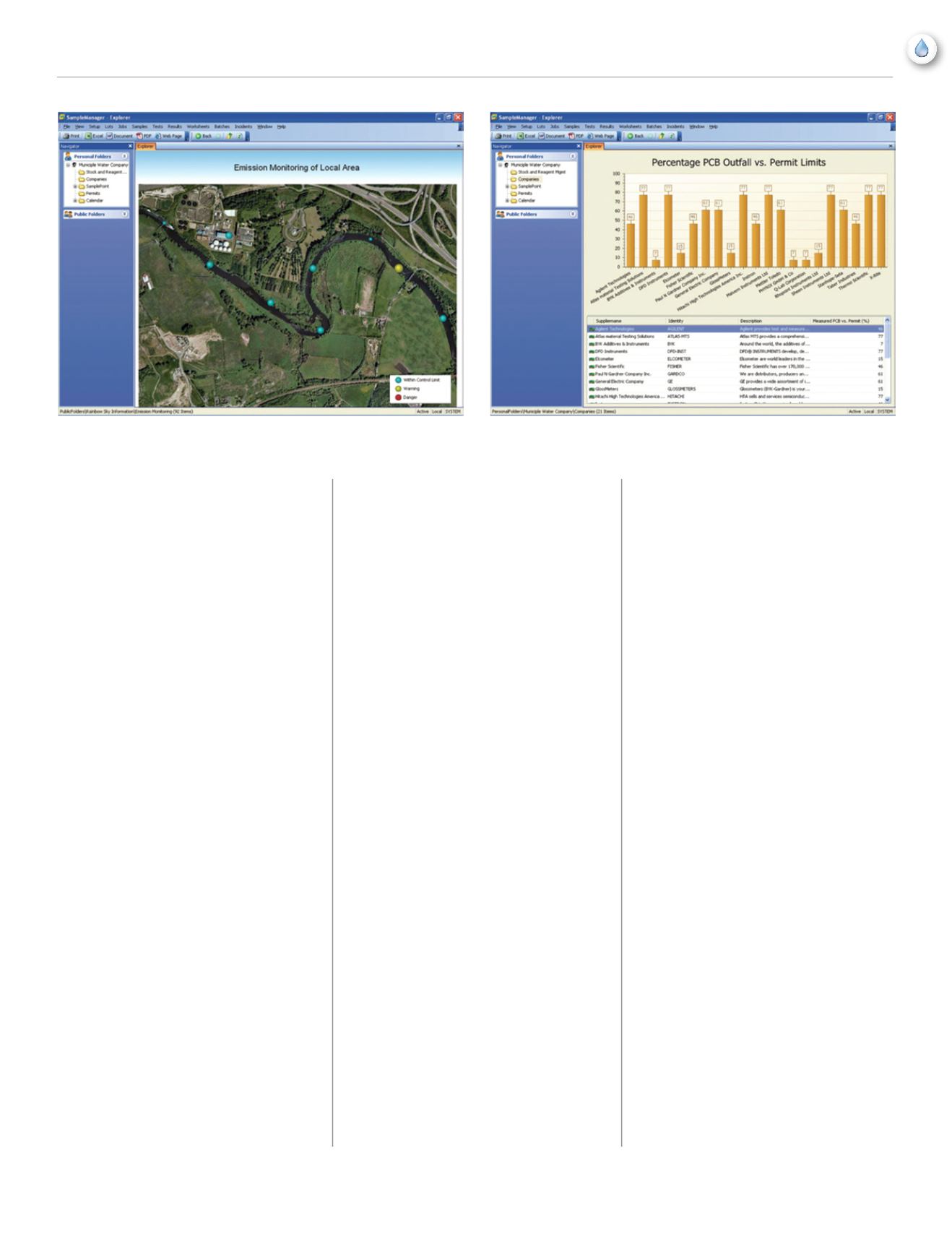

Data Visualization allows users outside the

laboratory to monitor field collection sites

quickly and easily within the LIMS.

Staff Training:

Training for each employee must

be closely monitored to ensure that they’re

up-to-date; otherwise results from any

part of an analytical process in which they

participate could be questioned. Maintaining

accurate and up-to-date staff competency

records is an onerous process that can be

simplified by storing all personnel training

records, certifications and permissions

within the LIMS.

Process Quality Assurance: Human error is

one of the most common causes of failure

in any process: small errors in the execution

of a GC analysis can render a result invalid.

To prevent this, labs must be able to

comprehensively monitor the execution of

laboratory processes and reference them to

individual results.

A LIMS achieves this by storing and

automating SOPs to walk staff through each

analytical or operational process. As staff

members progress through the steps of an

SOP, they mark their progress in the system,

creating real-time records to document that

they executed everything correctly. Process

errors can also be reported to a lab manager in

real time, allowing them to correct problems

before erroneous results are even reported.

Dashboards provide graphical representations

of information to allow laboratory management

and analysts to visualize critical information in

various forms.

Data Entry and Transcription: Manual data

entry errors made by staff can significantly

affect lab results. Even if a process is nearly

entirely automated, a single manual data

entry error can make the result indefensible.

ALIMS helps alleviate data entry concerns by

automatically collecting and aggregating lab

instrument data where they can be accessed

by staff or used by other instruments in the

lab. A vendor-agnostic LIMS is particularly

important here because it’s capable of

interfacing with a broad range of instruments

from multiple vendors.

Conclusion: Complete Traceability

The areas covered above by no means

comprise the exhaustive list of variables

involved in a typical GC analysis, and this

is just one of many analytical tests a water

industry labmight undertake. But the example

illustrates the point that there are many ways

for a single experiment to go astray and lead

to a disputed result. But defending results is

about more than simply verifying inputs and

outputs; it’s about documenting complicated

processes rigorously at every step without

pulling staff away from important work.

A LIMS can provide complete visibility into

processes and the staff that execute them.

Moreover, it can direct processes in a manner

consistent with SOP and, of course, quality.

This complete traceability streamlines

laboratory operations and provides the

defensibility that’s so important to lab staff.

For water industry labs, defending results is

a way of life but the task is made much easier

with software that looks over your shoulder,

defending you every step of the way.

About the Author:

Trish Meek is Director of

Strategy, Informatics, for Thermo Fisher Scientific.

Dashboards provide graphical representations of information to allow laboratory

management and analysts to visualize critical information in various forms.

Data Visualization allows users outside the laboratory to monitor field

collection sites quickly and easily within the LIMS.