A.C. Schultes of Carolina

3887 S. NC Hwy 41 Wallace, NC 28466

(910) 285-7465

www.acschultesnc.comJennifer Moore

Director of Marketing & Business Development

jennifer@acschultesnc.comCell: (910) 465-1876

Randy Hudson

Production Manager

randy@acschultesnc.comCell: (910) 617-3650

Singer Valve

1873 Scott Futrell Dr. Charlotte, NC 28208

(704) 391-5785

www.singervalve.comTodd Philbeck

Account Sales Manager – Southeast USA

todd@singervalvellc.comCell: (704) 574-0947

Company Overviews:

• A.C. Schultes of Carolina (ACSC) is a licensed, insured and bonded General

Contractor as well as full-service Utility and Well Contractor in both North Caro-

lina and South Carolina. ACSC provides a full range of water and wastewater

construction services to government utilities, private utilities, engineering firms,

industrial facilities, commercial farms, golf courses and more. A proven leader

in assisting environmental customers with complex water and wastewater

demands, we are experts at turn-key water and wastewater construction and

also offer emergency services.

• A.C. Schultes of Carolina is the exclusive dealer, field service provider and

repair facility for Singer Valve in the Carolinas.

• Since 1957, Singer Valve has been designing and manufacturing automatic

control valves for the global water industry including Pressure Reducing, Pres-

sure Relief/Sustaining, Altitude and Pump Control Valves.

Project Highlight:

Customer:

Craven County Water Department (New Bern, NC)

Project:

Potable Water Supply System

Details:

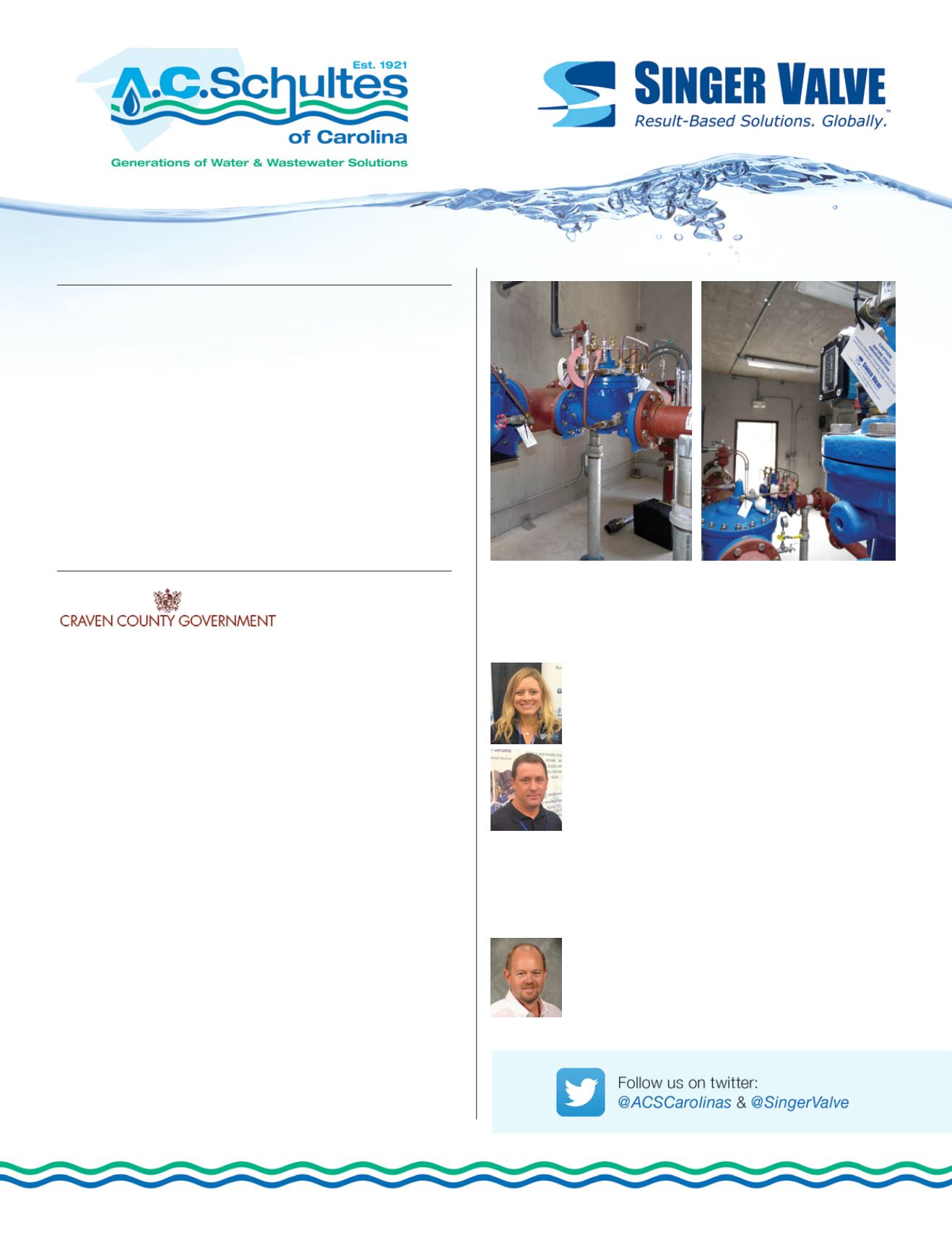

ACSC was subcontracted by Shook Construction (Apex, NC) to construct

eight (8) new water supply wells and their corresponding pump houses. Pump

station construction included the installation of all pumps, motors, piping and 24

Singer Valves – three (3) at each site. ACSC provided all of the labor, equipment and

materials to install the valves listed below:

• 106-DW Deep Well Pump Control Valve is the main valve in the three (3) valve application. This valve

is normally open, and, on pump start-up, a pilot solenoid is energized to start closing the valve at a rate

governed by the closing speed control.

– Initially, the valve discharges air, water and sand to waste. The open valve discharges all pump flow.

– As the valve closes slowly, flow is transferred to the main line smoothly, increasing the pipeline flow

without surges.

– When the valve is fully closed, all pump flow is in the pipeline, with no control valve losses.

– When shut-down is required, the pilot solenoid on the valve is de-energized to commence opening.

– The pump is kept running while the valve slowly opens. Increasing proportion of the flow is diverted to

waste with less passing through the check valve, until all flow is diverted through the nearly fully open

DW valve.

– The pipeline check valve closes quietly without surges.

– When the DW valve is almost fully open, a stem mounted cam triggers the limit switch to stop the pump.

– The valve prevents pump starting and stopping surges.There is no energy loss while pump is running.

– The valve separates opening and closing speed controls, discharges initial air/water silt to waste, on

well applications and discharges stagnant water at start-up from dormant wells

• The additional valves in this application are the 106-HC Hydraulic Check Valve that allows one way flow

only and the 106-RPS-L&H Surge Anticipating Relief Valve that is designed to anticipate surges to avoid

severe water hammer often associated with power failure surges.