28

NCRWA.COM|

Spring 2016

feature

Some additional points of consideration:

• The myth is the bigger the wire/heavier the

gauge, the stronger the signal. Not true.

Larger diameter is normally called out

for strength, not signal carrying qualities.

A common failure that happens during

installation is breakage. Size for size high

strength Copper Clad Steel (CCS) has

twice the break load of solid copper. This

allows smaller diameter wire to be used,

usually resulting in cost savings.

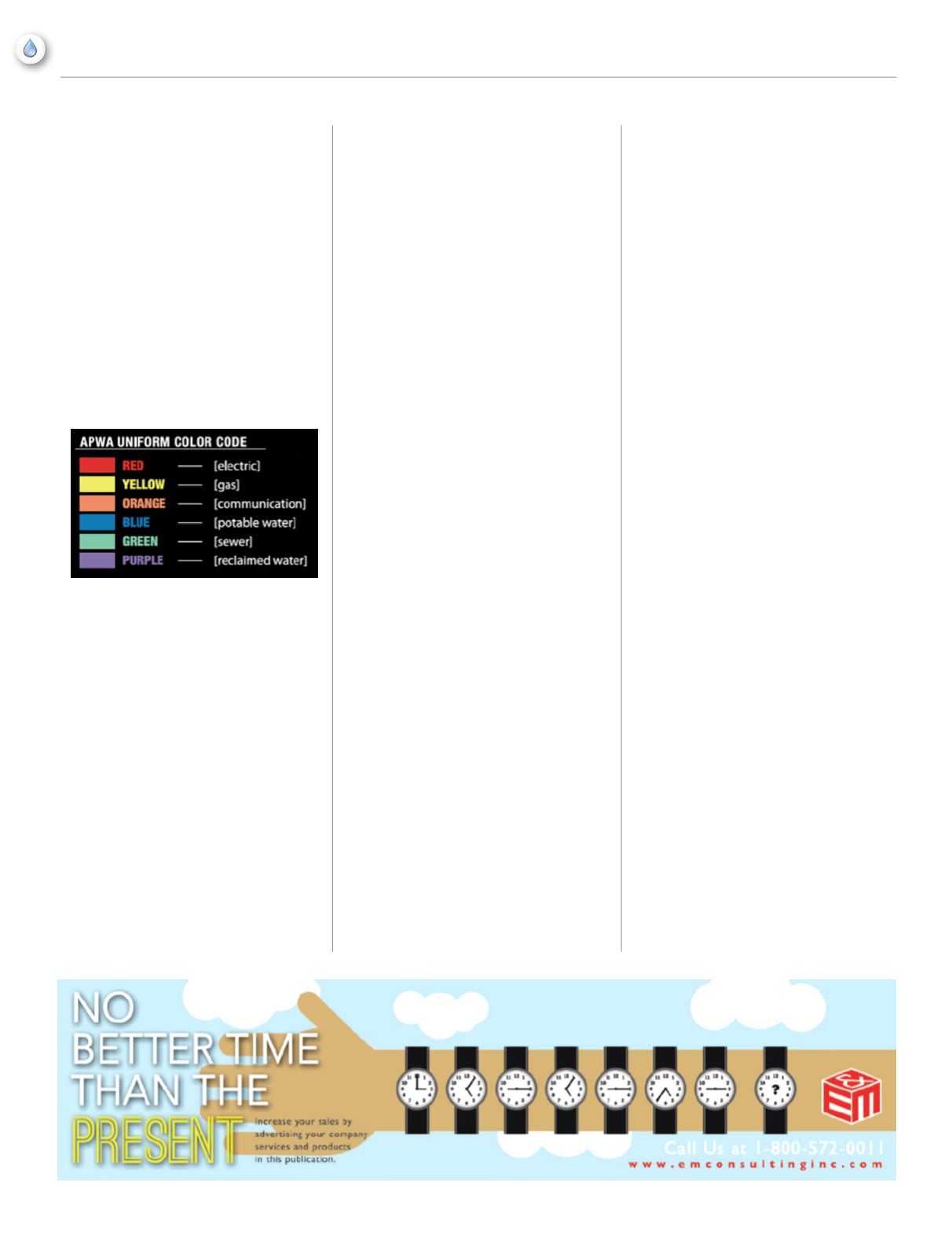

• Color Coding is simple, follow the APWA

uniform color code

• Many different jackets or coatings are

available. High Density Polyethylene

(HDPE) or High Molecular Weight

Polyethylene (HMWPE) are designed for

direct burial. Nylon or THHN, is not.

• Solid Copper or Copper Clad Steel (CCS)

work well and there’s no need for stranded

wire. High Strength Copper Clad Steel

(CCS) was introduced to the market in

2004 for tracer wire and it has a 2X strength

advantage over solid copper. Copper Clad

Steel has equal conductivity to solid copper,

but is usually less expensive.

• The best tracer wire in the ground, is

only as good as it’s connections. Proper

connectors, which protect from moisture

and corrosion, are extremely important.

Copperhead SnakeBite connectors and

3M DBR are two of the commonly used

moisture displacement connectors. One

should never twist the wires together and

merely wrap with electrical tape. Corrosion

will happen eventually and the locate signal

will be lost to ground at the connection.

• The tracer wire should be placed in the

same orientation to all installed pipe. Using

a spacer, taping the tracer wire to the pipe

every 8-10 feet in the three to six o’clock

position or specifying fill between the pipe

and tracer wire are all acceptable practices.

Taping the wire to the pipe helps prevent

damage to the wire during back filling or

when digging around the pipe in the future.

Installation of color coded warning tape

one foot above pipe will enhance utility ID

during excavation when repairs are needed.

Once tape has been found. Hand digging

should only be allowed

• The best tracer wire system is connected

with electrical current characteristics in

mind. Electricity will take the path of

least path resistance and shortest path to

ground. Good grounding and terminating

of the wire will improve quality of signal.

Using test stations to bring the tracer wire

above ground for ease of terminating a

signal is best. Grounding one or both ends

of the wire or introducing a small anode

may enhance signal strength.

• Different types of wire should be

considered for different installation

applications. Open ditch/direct bury does

not require as strong a wire as directional

drilling or pipe bursting. Consider

strength and coating type and thickness

when specifying wire, making sure there

will be no surprises after the project is

completed or when locating is required.

• Another very important step is to make sure

the contractor or city inspector performs

locate or conductivity test prior to signing

off on the project. It is much easier to

correct any issues promptly as opposed

to months or years later when locate is

required and the piping cannot be found.

Like your fire hydrant, curb stop, manhole,

piping and other important components of

your system, tracer wire should be taken just

as seriously. It’s ultimately an inexpensive

insurance policy. Especially if you weigh

the cost of repairs once a utility has been

damaged due to not being able to locate.

Write specifications to cover the entire tracer

wire system. Not just wire, but connectors,

test stations, and procedure as to how you

want the components installed.

The Minnesota Rural Water Association

recently adopted such an example specification

and installation instructions along with

drawings which can be viewed on their official

website here:

http://www.mrwa.com/PDF/TracerWireSpecGuideFinalweb3.pdf

If you would like more information including

example specifications, details, installation guides

to provide a more traceable system, please contact:

Brad Penley

Porter Associates, Inc

brad@porterassociates.com704-202-6429