feature

T

ABSTRACT:

This article will review the

properties and selection criteria for

dynamic seals in wastewater applications.

The impacts of the inherent compromise

between sealing ability and seal life will

be reviewed along with the materials,

processes and options that may

affect seal mechanics and application

engineering. This article will contain a

chart of materials and properties; photos

of seal failure impacts; and a review of

potential dynamic seal failure-modes

relative to screening and membrane

protection. Recommendations relative to

seal selection, sealing process strategies

and other options will be included.

he most common modes of seal failure are by

fatigue-like surface embrittlement, abrasive

removal of material, flex-cracking and

corrosion.Abrasive particles in the wastewater

stream have a strong influence on the wear

resistance of seals, the wear rate of the seal

increasing with the quantity of environmental

contamination. A good understanding of the

wear mechanism involved will help determine

potential seal deterioration. Contaminants

from the environment such as sand can

become embedded in the seals causing

abrasive cutting. Elastomer wear is analogous

to metal degradation.

As the use of specialized membranes in the

wastewater industry to meet more stringent

standards and to support the trend toward

direct reuse increases, the reliability of

dynamic seals in pre-screening technologies

becomes more critical. This brings the focus

to dynamic seals as the weakest link in the

protection of downstream processes. For this

reason, the specification of the appropriate

seal material for each application and sealing

strategies becomes imperative. This is

because seal failure is progressive and can go

undetected until it becomes catastrophic to

high-value downsteam technologies.

Process Protection—an Essential

Membrane technology is increasingly central

to wastewater processing. This trend can be

expected to grow with the expanding focus on

the reuse of wastewater. However, membrane

technology is especially vulnerable to

oversized debris within the waste stream. This

vulnerability in turn places a special emphasis

on the reliability of prescreening technology.

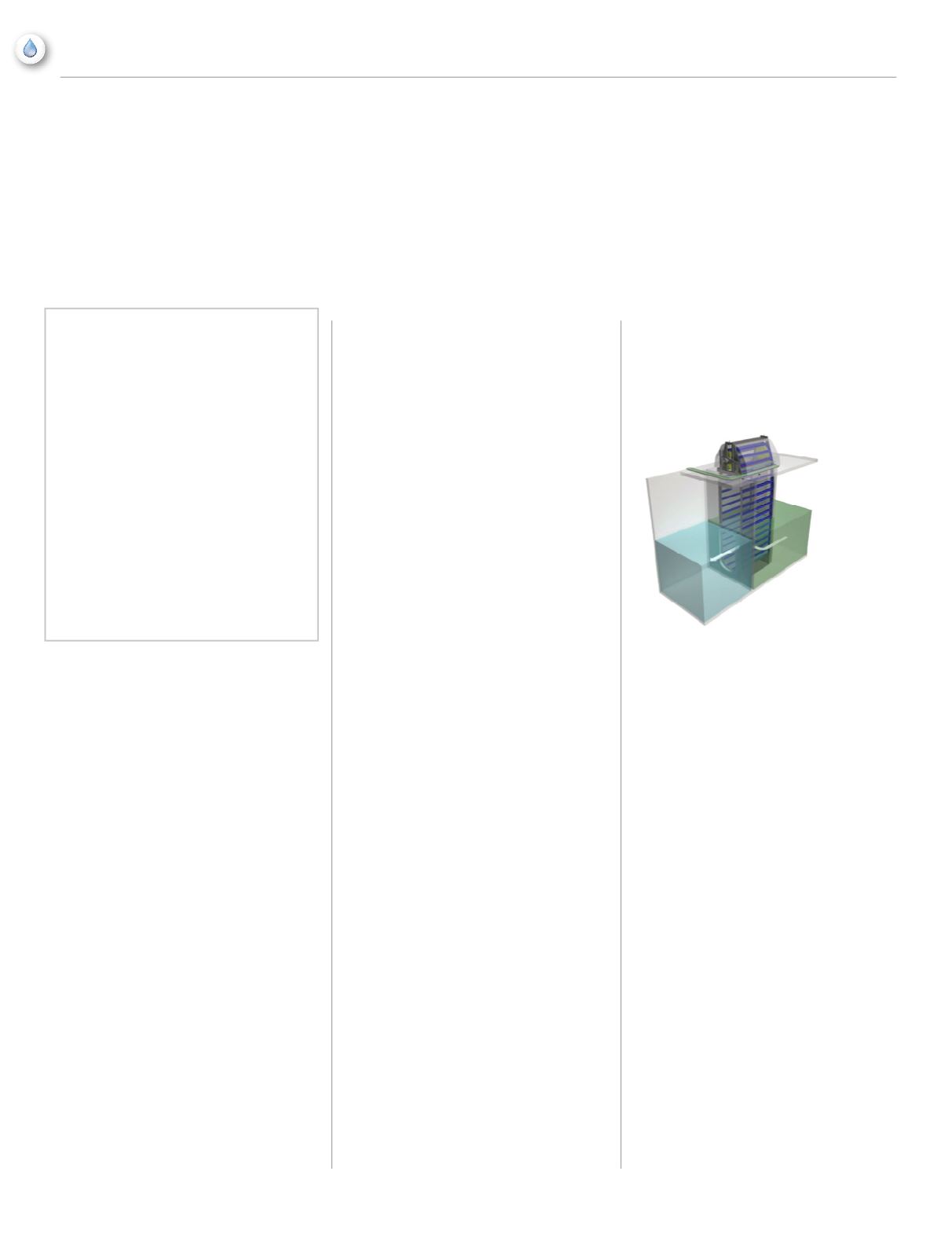

In many cases, this critical prescreening step

is performed by band-type screens, which

rotate perforated metal panels in front of

the process flow to capture oversized debris.

To accomplish the movement of the metal

panels—which is necessary for the removal

of debris—these panels are mechanically

rotated. Seals are used to isolate the front of

the panels (influent-facing) from the back of

the panels (effluent-facing). Seals are also

used to prevent leaks of influent into the

effluent stream at the rotating edge of the

band of assembled panels

(see figure 1)

. At

the rotating edge a lip-seal is used. This seal

is subjected to various type of wear from

abrasion at the surface-to-surface contact as

well as from material (i.e., sand, grit, glass,

etc.) leeched from the debris stream. The

seals between the metal perforated panels are

subjected to a continuous cycle of flexing as

the band of panels rotate for the purpose of

debris removal.

This means that in many cases, the protection

of the downstream membrane(s) depends on

two types of rotating seals—specifically seals

that can abrade and fail (at the rotating edge)

as well as seals that can fatigue, elongate and

fail (between the individual perforated metal

panels). For this reason, a careful compromise

has to be made between a variety of wear

factors. These factors include: the elasticity of

the seal, the hardness of the seal, the tensile

strength of the seal as well as several other

basic seal properties.

About Seal Properties

Seals for use in rotating assemblies (aka,

dynamic seals) are available in a spectrum

of materials with specific properties. Some

are harder and longer lasting, but sacrifice

flexibility and resiliency to achieve this

goal. Others are resistant to swelling

and degradation from chemical agents at

the expense of elasticity. This inherent

compromise in seal properties make seal

selection a challenging compromise. (

See

Seal Material Overview and Chart A

)

Tests conducted at Massachusetts Institute of

Technology (MIT) show that the seal wear

process occurs in two stages: the break-in

period and the aggressive wear period. During

the break-in period the seal does not wear.

During the aggressive wear period, however,

particles under the contact band cluster and

form an abrasive front that erodes the seal lip

at a rapid rate.

In the seal-wear example shown below,

(see

figure 2)

, the penetration of particles into

the contact band of the seal as a function of

By Mike Pruitt, Duperon

20

NCRWA.COM|

Winter 2015

DYNAMIC SEALS

THE “SEALING ABILITY VERSUS SEAL LIFE” COMPROMISE

MATERIALS, PROCESSES, OPTIONS

Figure 1:

Typical band-type

perforated screen.