Winter 2015

NCRWA.COM21

feature

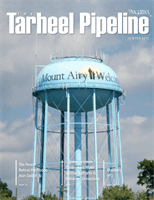

cycles of operation is shown. Seal wear is

measured as the percentage of the seal lip that

the abrasive slurry has penetrated. Note that

there are two distinct regions of operation.

The break-in period of wear is characterized

by a very low wear rate and can be seen as

the region from 0 to 7,000 cycles of operation.

The aggressive wear period occurs after 7,000

cycles of operation.

Figure 2:

Seal Failure Example

Rotary Type Seals (Dynamic Seals)

Will Fail—It’s Inevitable

Seals employed on rotating elements will

ultimately fail. It is only a matter of when.

Rotating seals begin to wear from the moment

they are put into service. The rate of wear

is highly variable depending on: the seal

materials used in their manufacture; the nature

of the debris to which the seals are exposed;

the accuracy of the seal alignment with

mating surfaces; the smoothness of the mating

surfaces; average operating temperatures;

exposure to certain chemical substances;

exposure to sunlight; and, of course, the age of

the seals. The complexity of these interacting

factors make it difficult to predict the life of

a seal in a rotating application. Leakage from

wear, elongation or physical damage can easily

go undetected and potentially cause initially

imperceptible damage to downstream process

such as membranes

(see figure 3)

.

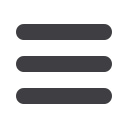

Figure 3:

A membrane filter damaged by over-

sized debris as a result of seal leakage.

Fixed-Element Seals are an

Option for Critical Applications

Fixed-element or static seals—seals which

do not move—are perhaps the best option for

applications that require an absolute barrier to

debris. Perforated screens with fixed-element

seals move the cleaning mechanism rather

than the perforated metal screen and thereby

eliminate any opportunity for incremental

leakage or catastrophic seal failure, such

as can occur when using a dynamic sealing

strategy. In contrast, sealing integrity is

absolute with a static seal as there are no

cycling variances; no abrasive effects, and no

potential for incremental leakage.

Given the capital expense of membrane

technology in relation to the cost of protective

screening, one can expect a trend toward

static sealing strategies.

Seal Material Overview

2

Natural Rubber:

Features:

Natural Rubber features high tensile

strength; high resilience, high abrasion and

high tear resistance properties, with a good

friction surface and excellent adhesion

to metals. Natural Rubber features good

resistance to organic acids and alcohols, with

moderate resistance to aldehydes.

Limitations:

Not widely used in sealing industry

due to poor compression set performance at

elevated temperature and lack to resistance to

petroleum based fluids.

Ethylene propylene:

Features:

When compounded using peroxide

curing agents, high temperature service can

reach +302°F. Good resistance to acids and

solvents (i.e. MEK and Acetone).

Limitations:

Have no resistance to

hydrocarbon fluids.

Chloroprene (Neoprene®):

Features:

Neoprene can be used in

innumerable sealing applications due to

its broad base of such desirable working

properties as: good resistance to petroleum

oils; good resistance to ozone, sunlight and

oxygen aging; relatively low compression

set; good resilience; outstanding physical

toughness; and reasonable production cost.

Limitations:

Neoprene

®

is generally attacked

by strong oxidizing acids, esters, ketones,

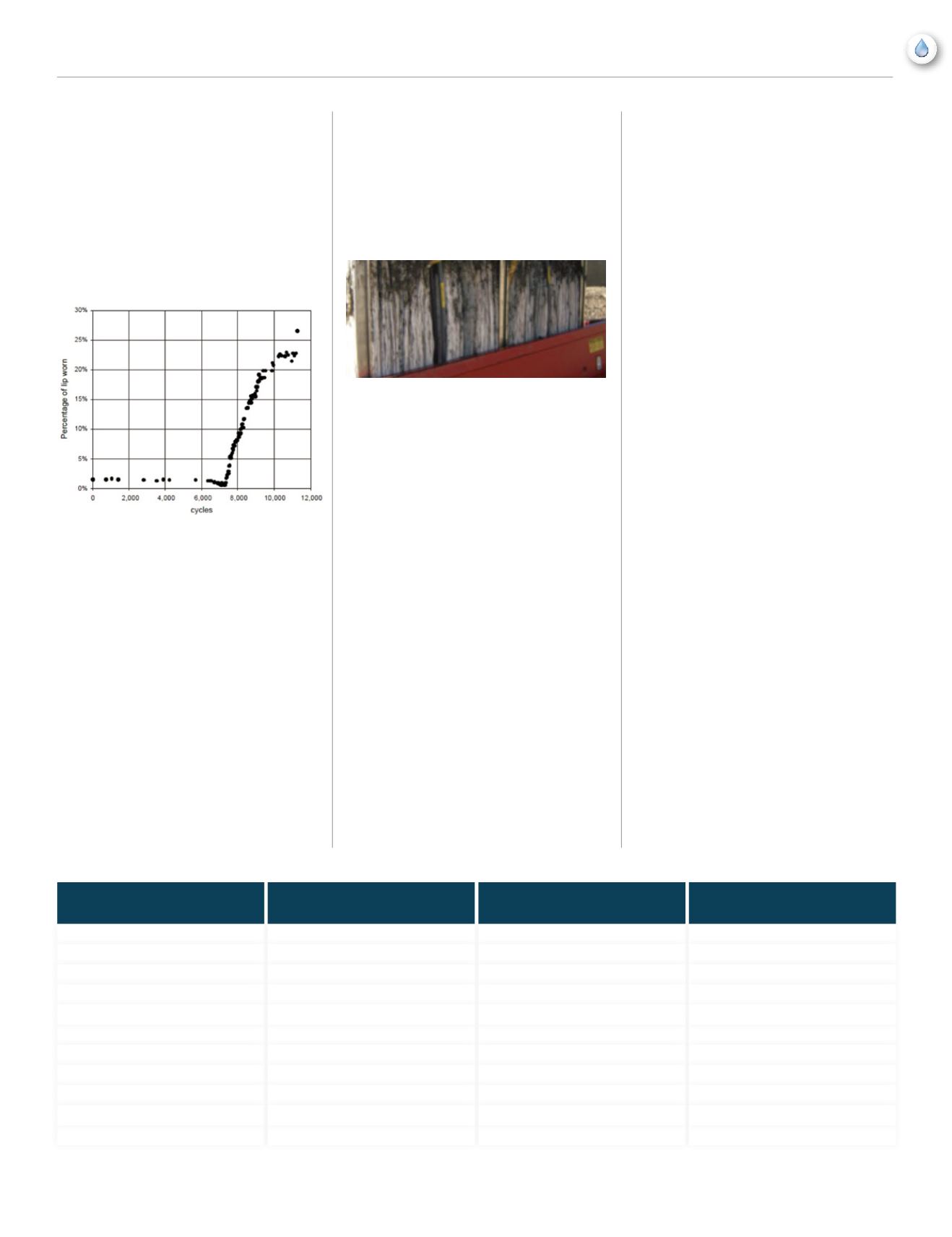

SEAL MATERIAL

TEMPERATURE RANGE

Degrees F

HARDNESS/DUROMETER

Shore A*

TENSILE STRENGTH

Characteristics**

Natural Rubber

-58 to +158

40 to 90

G-E

Ethylene Propylene

-40 to +225

40 to 95

G

Chloroprene (Neoprene®)

-40 to +250

40 to 90

F

Nitrile (Buna-N)

-40 to +257

40 to 90

G

Nitrile (Hydroginated)

-30 to +300

50 to 90

G-E

Polacrylate

-25 to +300

40 to 90

F

Flurosilicon

-75 to +600

40 to 80

P

Flurocarbon (Viton®)

-13 to +446

55 to 90

F

Silicon Rubber

-85 to +400

5 to 80

P

Butyl Rubber

-50 to +250

40 to 90

F-G

Polyurethane

-30 to +175

70 to 90

E

*Shore A scale: 100=the hardness of glass or steel—scale is not proportional.

**E=Excellent, G=Good, F=Fair, P=Poor

Chart A