B

24

NCRWA.COM|

Winter 2015

feature

iofilm is the basis of biofouling. The term “biofilm” usually generates

a vision in most people’s minds of a wafer thin shinny substance that

lightly coats whatever it is in contact with. Well, for a very brief moment

in its existence, it may have that appearance. In reality, biofilm beyond

its planktonic and initial attachment phases more resembles the growth

of sea coral as opposed to a thin coating.

There are several “pieces to the puzzle” of the impacts to cost created

by uncontrolled biofouling. This article attempts to put at least some of

those pieces together in a useable fashion.

Biofilm bacteria are actually colonies of various bacteria that all have

the characteristic of producing a “slime coat” around the bacteria. This

polysaccharide material is extremely sticky with excellent adhesive

abilities. The size of this slime coat in relationship to the size of the

bacteria is quite large. If a person standing in the middle of an NFL

football stadium were to represent the single bacteria, then the outside

edges of the stadium would approximate the size of the slime coating.

The polysaccharide slime coat serves several functions. All of these

functions combined help the biofilm colony thrive. Some simple

descriptions are listed below.

One function of the slime coat is to trap nutrients found in the water so

they can be brought to the cell for food. Nutrients can be organic and/or

inorganic. As an example, dissolved iron in the water is used by some

of the biofilm colony as food. The slime coat also traps other bacteria,

protozoa, viruses and oocysts. After the biofilm has metabolized its

food, the waste is passed through the slime coat and “stuck” to the

surface material the colony is growing on. In many cases the waste is

composed primarily of iron. But the waste is derived from whatever the

biofilm cells are feeding on. Most commonly, this deposited waste is

observed by utility staff as tubercles and/or corrosion.

This filtering characteristic of the slime coat results in the concentration

of material trapped there. Eventually, this concentrated material can be

ejected from the biofilm colony to become free floating in the water

flow. It then either re-attaches itself further downstream or is delivered

to the consumer. The slime coat protects the bacteria cell from harm by

disinfectants or antibiotics. The slime coat reacts with the disinfectant

reducing its effectiveness. More disinfectant is needed to sustain

desired free disinfectant residuals. This reaction with the slime coat

also increases the level of disinfectant byproducts. The precursor for

the formation of disinfectant byproducts is Naturally Occurring Matter

(NOM). So, the larger the concentration of biofilm colonies afflicting

the infrastructure, the greater the production of disinfectant byproducts;

AND more disinfectant is required to maintain desired disinfectant

concentrations. More money is spent on disinfectant, and even more

money is spent attempting to lower the disinfectant byproduct levels.

The slime coat is also used for quorum sensing. This is where the bacteria

have the ability to recognize other biofilm bacteria and join with them.

Think of a biofilm colony like a city. Its citizens work collectively to

make life better and safer. With quorum sensing the biofilm colonies

work together to ingest more food and protect the biofilm cells. This is

how the biofilm colonies grow and expand.

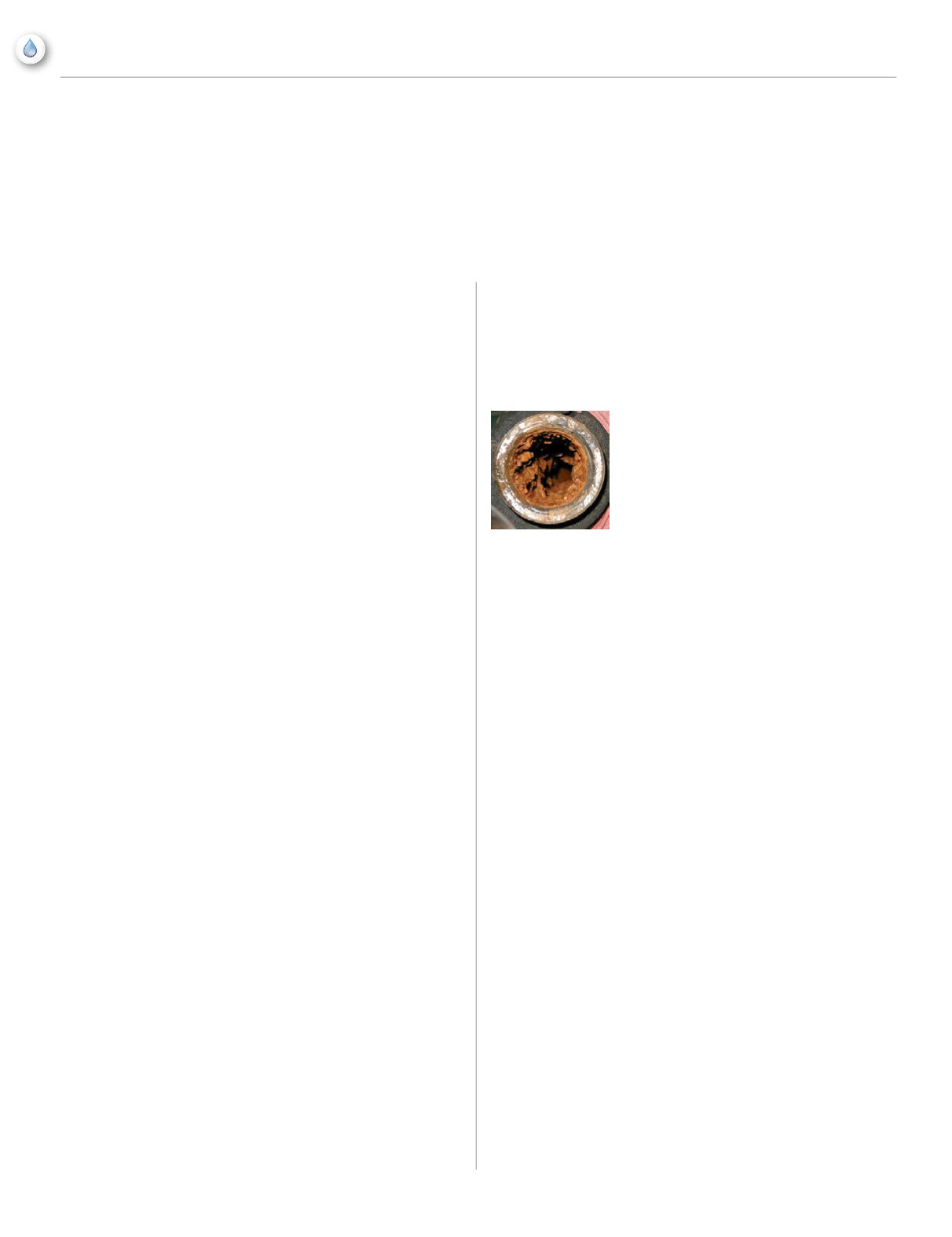

This cut away of a pipe gives an idea of what

biofouling can do to the interior of a pipe.

The cross section of the pipe is significantly

reduced. The friction loss through this pipe is

severe. So not only is there additional electrical

cost to overcome the reduced inside diameter

of the pipe, the cost is even higher still due

to the friction loss created by the Microbial

Induced Corrosion. In other words, the biofilm has matured to such a

degree it is severely affecting the pipes effectiveness.

It is easy to see the nature of the biofilm colony growth creates pockets

that can protect the biofilm cells from the effects of whatever disinfectant

is used. What might a pipe with no disinfection or interrupted disinfection

look like? Also, how effective can flushing be? Flushing can only remove

loose, unattached material IF sufficient velocities are achieved. Now

imagine the pipe pictured here as the casing of a well. Since a well has

perforations (or screen sections) the biofilm growth occurring on the

inside of the well casing is also happening on the outside of the well casing.

There is typically no treatment being done to the water at this stage. As the

pathway in the screens becomes smaller and smaller, less and less water

passes through the screens. What about the pore space in a gravel pack? Or,

what happens to the water bearing strata outside the well screens?

Reduced flow through the screens causes one or two things to happen.

1. If there are no other sections of screens in the well case, then the draw down

level will continue to increase until it reaches the point where the pump can

pump more water than the restricted well case screens can deliver. The pump

sucks air.

2. If there is more than one section of screens in the well case, as one section

becomes increasingly restricted, more water is pulled from the other sections of

screen which are less impacted. This can change the raw water characteristics

of the well. This shift from pulling water from one layer to another layer can

result in a change in raw water quality. An example of this is where one layer

has an arsenic concentration below the MCL, and another layer has an arsenic

concentration above the MCL. Initially, the water blended from the two layers

resulted in the overall raw water concentration below the MCL. If the flow from

the layer with the lower concentration is reduced, and the difference is made

up from the layer with the higher arsenic concentration, then the blended

arsenic concentration will increase.

By Bruce Baker, Consultant, BRB Consulting Service

IMPACTS OF

BIOFOULING

ON DRINKING WATER INFRASTRUCTURE